Maintenance management system PATRIOT®

Maintenance management system PATRIOT® 3.0 supports the restoration of objects using all maintenance strategies - Corrective, Preventive, Diagnostic und Predictive maintenance.Maintenance is a valuable instrument of MES

The Patriot® 3.0 maintenance management information system belongs to the group of systems known as CMMS (Computerized Maintenance Management Systems) or EAMS (Enterprise Asset Management Systems). With its help comes an endless possibility to manage the maintenance of both production and non-production assets, technological units and individual machines. The system can also be used to manage the maintenance of buildings and their parts. Within the MES, the maintenance management system can coordinate downtime with production schedules and predict the time of failure of production equipment. This contributes to increased utilisation of production assets at optimum maintenance costs and high reliability.

The PATRIOT® 3.0 maintenance management information system is modular:

- The basic set of necessary functionalities includes

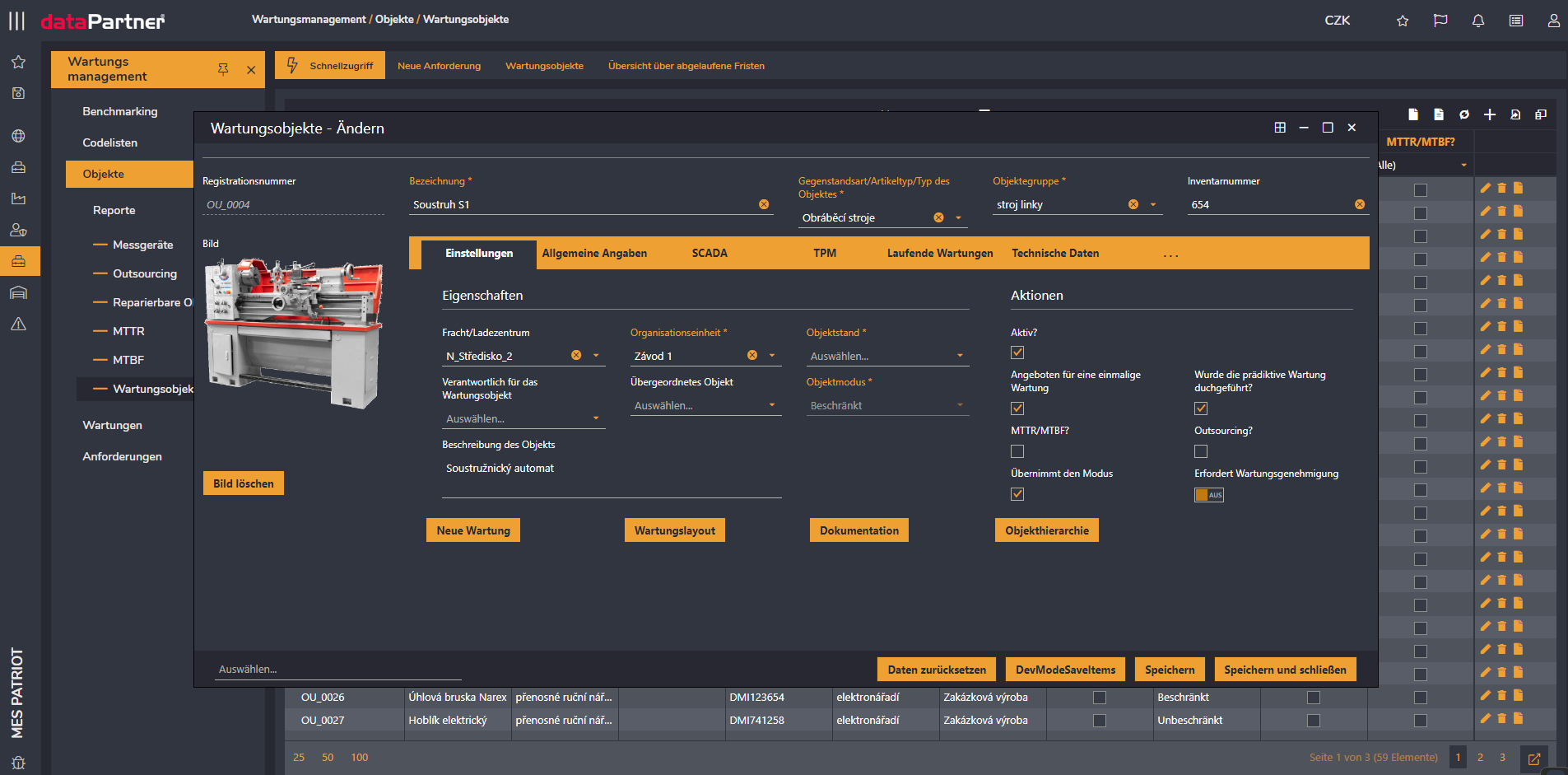

- Maintenance object register (description of technical locations, equipment criticality, hierarchy)

- Human resources list (directory of people including skills and course tracking)

- Technical documentation of machinery and equipment (electronic archiving)

- Maintenance kiosks (screens for maintenance staff to work with the system)

- Maintenance requirements (work orders, work reports)

- Reports (graphs and outputs of maintenance activities)

- Checklists, job descriptions, missed deadlines (summary report)

- Documentation management (documentation and attachments in digital form, electronic archiving)

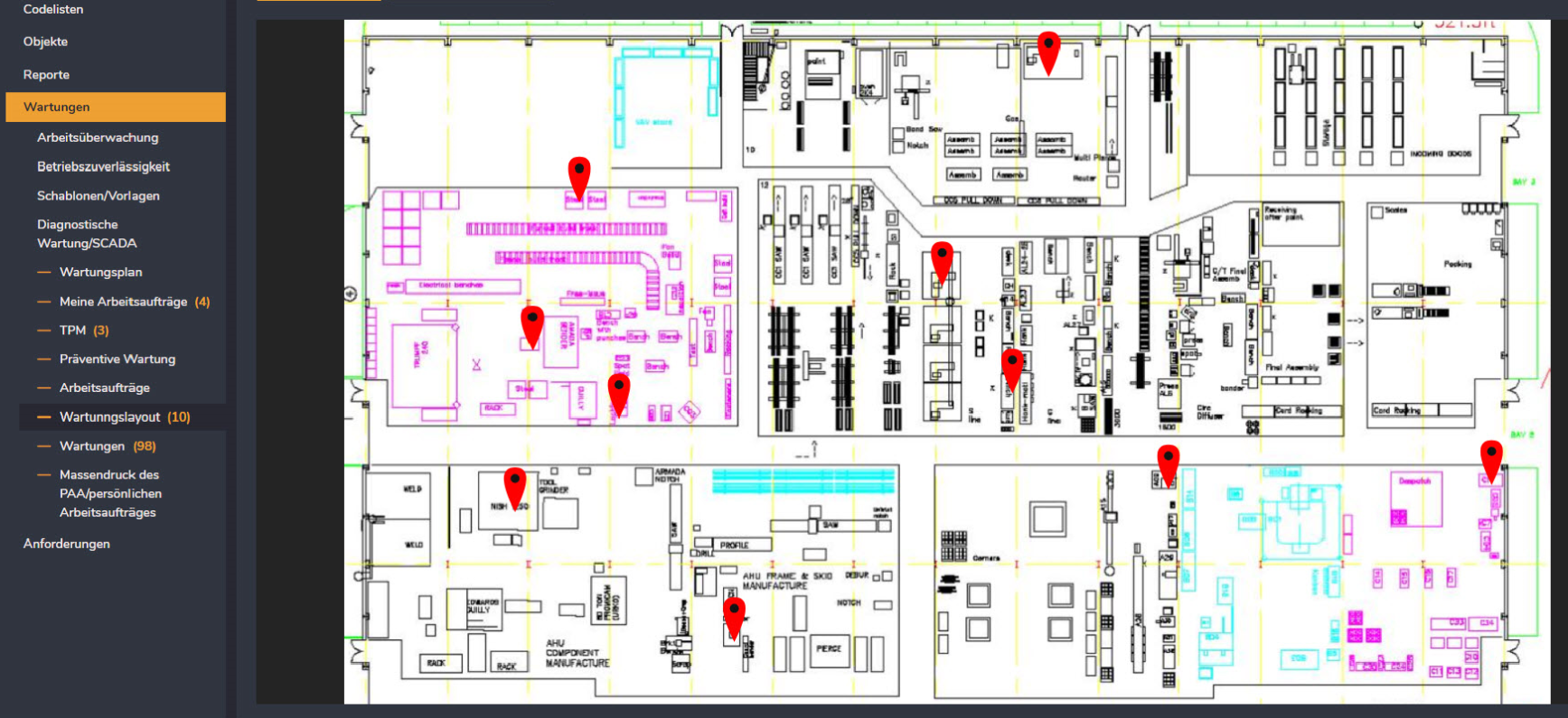

- Layout of maintenance sites (map with marked maintenance objects in failure)

- Notification, escalation (monitoring of maintenance requirements)

- Cost tracking

- Optional additional modules:

- Maintenance scheduling (event calendar)

- Resource planning (personnel, material and ND, tools, production time, finance, external resources)

- Spare parts inventory and inventory management

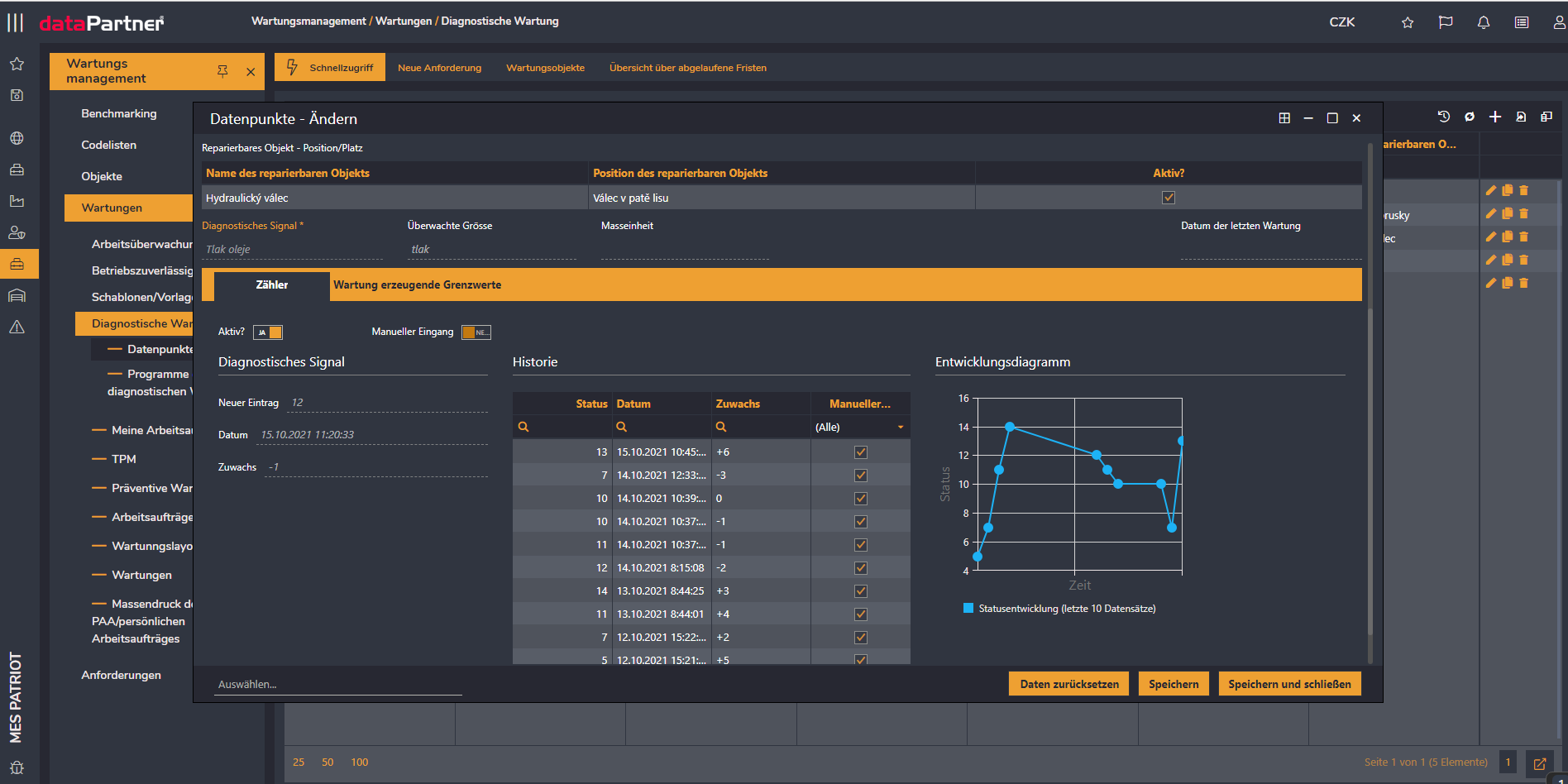

- Collection of operational data, monitoring of technical status (SCADA category)

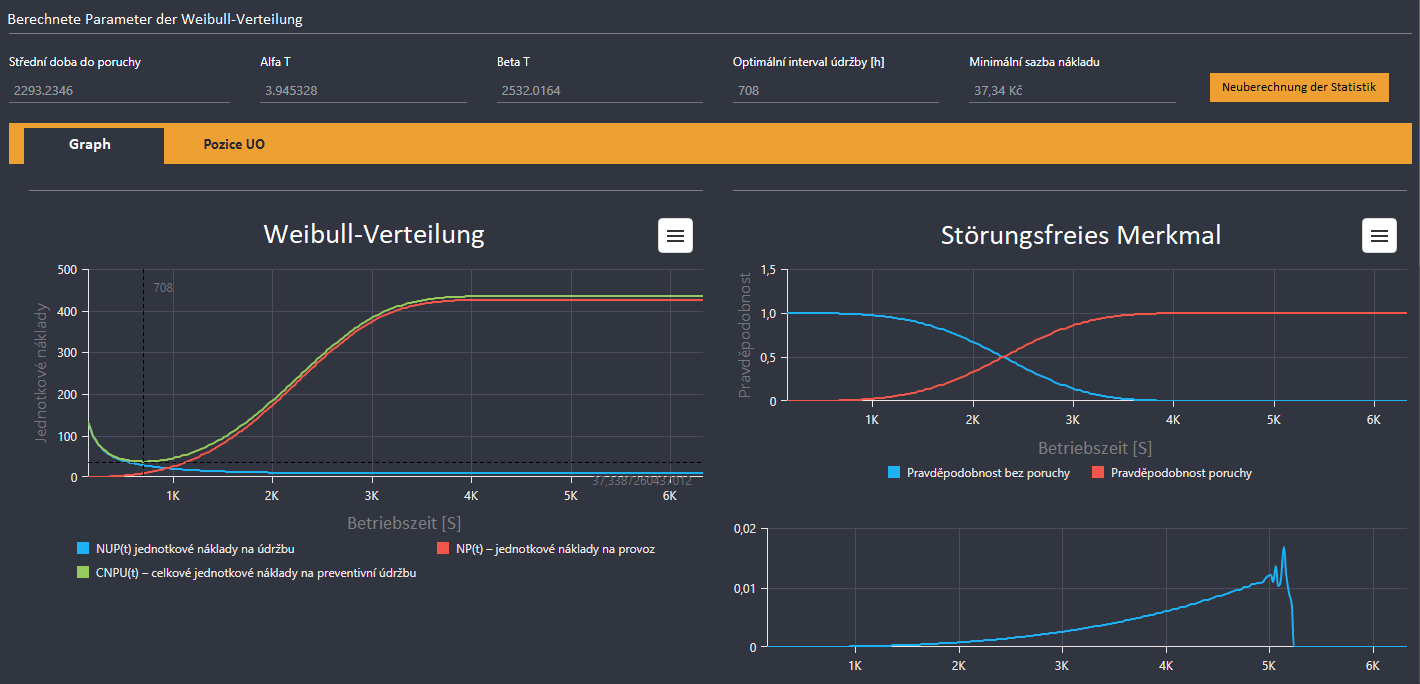

- Operational reliability of critical equipment (using Weibull analysis)

- Predictive maintenance and preventive maintenance optimization

- Maintenance planning and scheduling based on OEE and other maintenance performance indicators

- General integration module with ERP system

- Mobile apps for phones and tablets (diagnostic data collection, reporting of maintenance activities, access to documentation)

- Augmented reality data visualisation

Benefits of using the PATRIOT Maintenance Management information system

It minimizes the number of unplanned downtimes and thus increases the reliability of production, can significantly extend the service lifespan of production equipment and thus increase the economy of production. It optimises the deadlines for the execution of planned maintenance tasks contributing to the reduction of operating costs. This contributes to higher utilisation of production assets at optimum maintenance costs and to maintaining high reliability.

Reports on maintenance activities are also a very viable tool. The reports can quickly and clearly evaluate the current state of maintenance from multiple perspectives; the frequency of failures in individual equipment or production units based on historical and current data. Reports can be selected from a set of proven and frequently required reports or can be individually prepared. Virtually every report provides the option to customize and save filters that allow further customization of the view of the required data.

Correct terminology and an ergonomic and intuitive user interface play a very important role. The terminology is in line with EN 13306 (010660) ed. 2: Maintenance - Maintenance Terminology which unifies terms and facilitates communication across the maintenance and asset management community. The ergonomic and intuitive user interface is designed in a unified spirit and allows for easy and intuitive operation at the level from the maintenance terminal screens to the planning forms. The user interfaces also include mobile devices, smartphones and tablets which provide a working environment consistent with the entire system. This fact significantly contributes to the ease of implementation of PATRIOT® 3.0 by end customers and its smooth acceptance by all employees.