The SPS covers the entire spectrum of smart and digital automation. Discover the exciting world of automation!

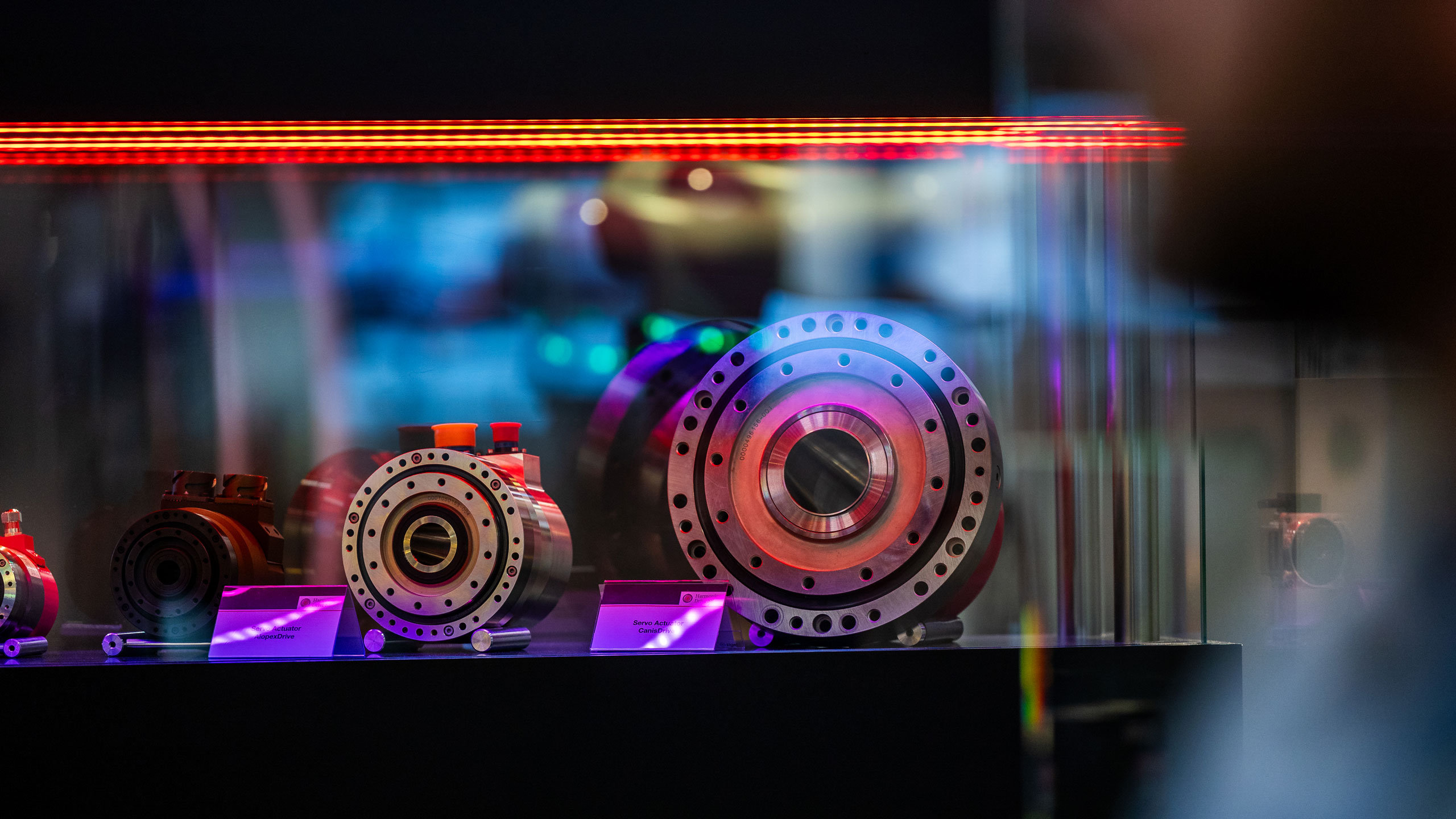

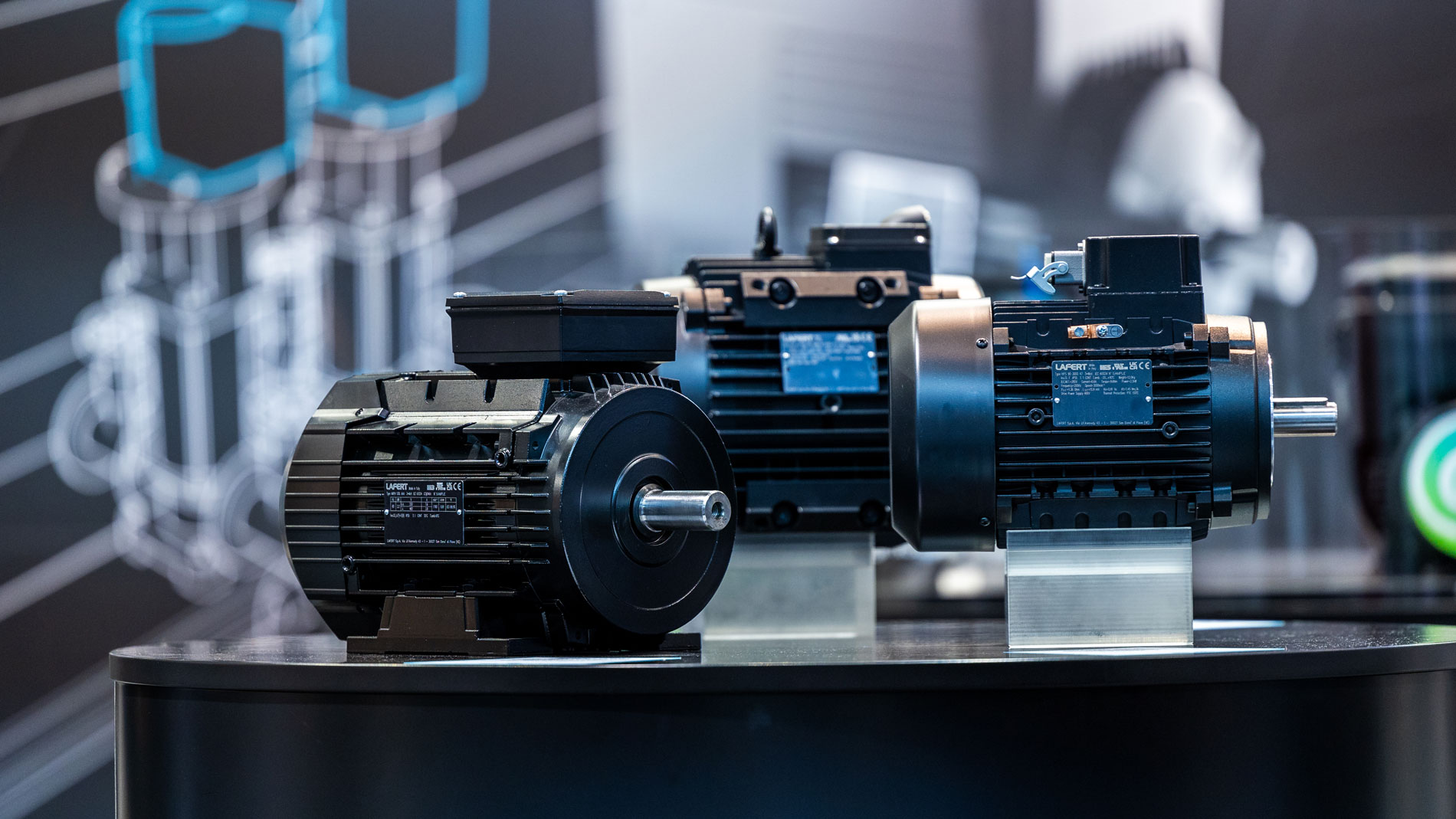

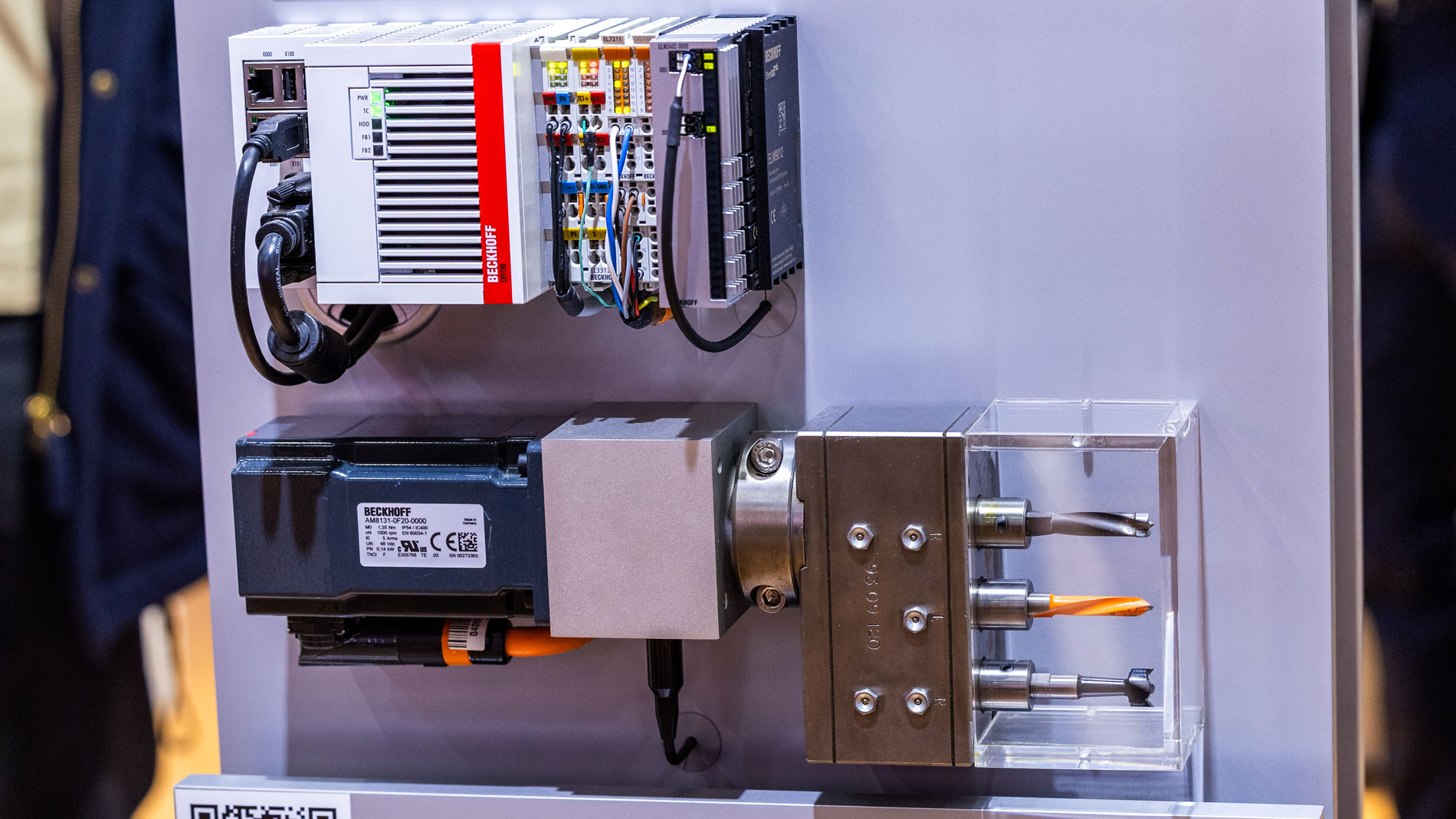

Electric drives / motion control

Electric drive technology in factory automation refers to the use of electric motors and their control systems to move machines and equipment. It converts electrical energy into mechanical motion such as rotation, lifting or linear movement. Using frequency converters, servo controllers and intelligent control systems, speed, torque and position can be precisely regulated. It forms the backbone of automated production processes by executing movements reliably and repeatedly.

Mechanical infrastructure

Mechanical infrastructure in factory automation includes all physical base elements that support, guide and stabilize machines and equipment. This comprises frames, structures, supports, foundations and housing constructions. It forms the static basis on which drives, sensors, controllers and tools are mounted. Guides, rails and bearings ensure precise movements and minimize friction and wear. Transport systems such as conveyor belts, chains or rollers are also part of the mechanical infrastructure. Safety devices like protective covers, fences and mechanical interlocks ensure the protection of people and machines.

Sensors and system solutions

Sensors detect physical variables such as position, pressure or temperature and convert them into electrical signals for control systems. Typical sensors include proximity switches, light barriers, camera systems and rotary encoders. They enable real-time monitoring and form the basis for quality assurance and efficient processes. Modern sensor systems are networked, communicate via fieldbuses or Industrial Ethernet, and use intelligent signal processing or AI to identify patterns and report errors at an early stage.

Control technology

Control technology in factory automation includes all systems that control machines and equipment logically and in the correct sequence. Sensors provide input signals that are converted into output signals for actuators and drives. The goal is automatic, reliable and repeatable process control. Core components include PLCs, industrial PCs and embedded systems. Processes are defined using programming languages such as STEP 7, IEC 61131-3 or high-level languages. Control technology is integrated into networks via fieldbuses and Industrial Ethernet, enabling the starting, stopping, synchronizing and optimizing of processes. Modern control systems are networked, modular and cloud-enabled – in line with Industry 4.0. Safety functions such as emergency stop or safe states are an integral part. Control technology is considered the “brain” of factory automation and ensures intelligent production.

Software & IT for manufacturing

Modern manufacturing is based on powerful software and IT infrastructure that digitally maps, controls and optimizes production processes. Systems such as MES, ERP and process control technology connect machines, sensors and controllers with higher-level IT structures and enable seamless communication from the shop floor to management.

A key component is Industrial AI: Artificial intelligence analyses production data in real time, identifies patterns and makes autonomous decisions. It increases efficiency through predictive maintenance, quality control and intelligent robotics. Combined with cloud and edge computing, AI is deployed directly at the machine or on central platforms.

IT security solutions protect networked systems against cyber threats. Digital twins, data analytics and explainable AI ensure transparency and trust. Overall, software and IT form the foundation of the smart factory – intelligent, connected and flexible.

Interface technology

Interface technology includes all technologies that enable the exchange of information and signals between different systems. It connects sensors, actuators, controllers, drives and IT systems – electrically, optically or digitally. Typical interfaces include fieldbuses, Industrial Ethernet, IO-Link or serial standards such as RS-232/RS-485. They ensure uniform communication and compatibility between components from different manufacturers. Modern interfaces also enable diagnostic functions, condition monitoring and parameter changes. Interface technology plays a key role in connectivity within the framework of Industry 4.0. Standardization helps reduce integration effort and costs. As the “nervous system” of factory automation, it connects all elements reliably and efficiently.

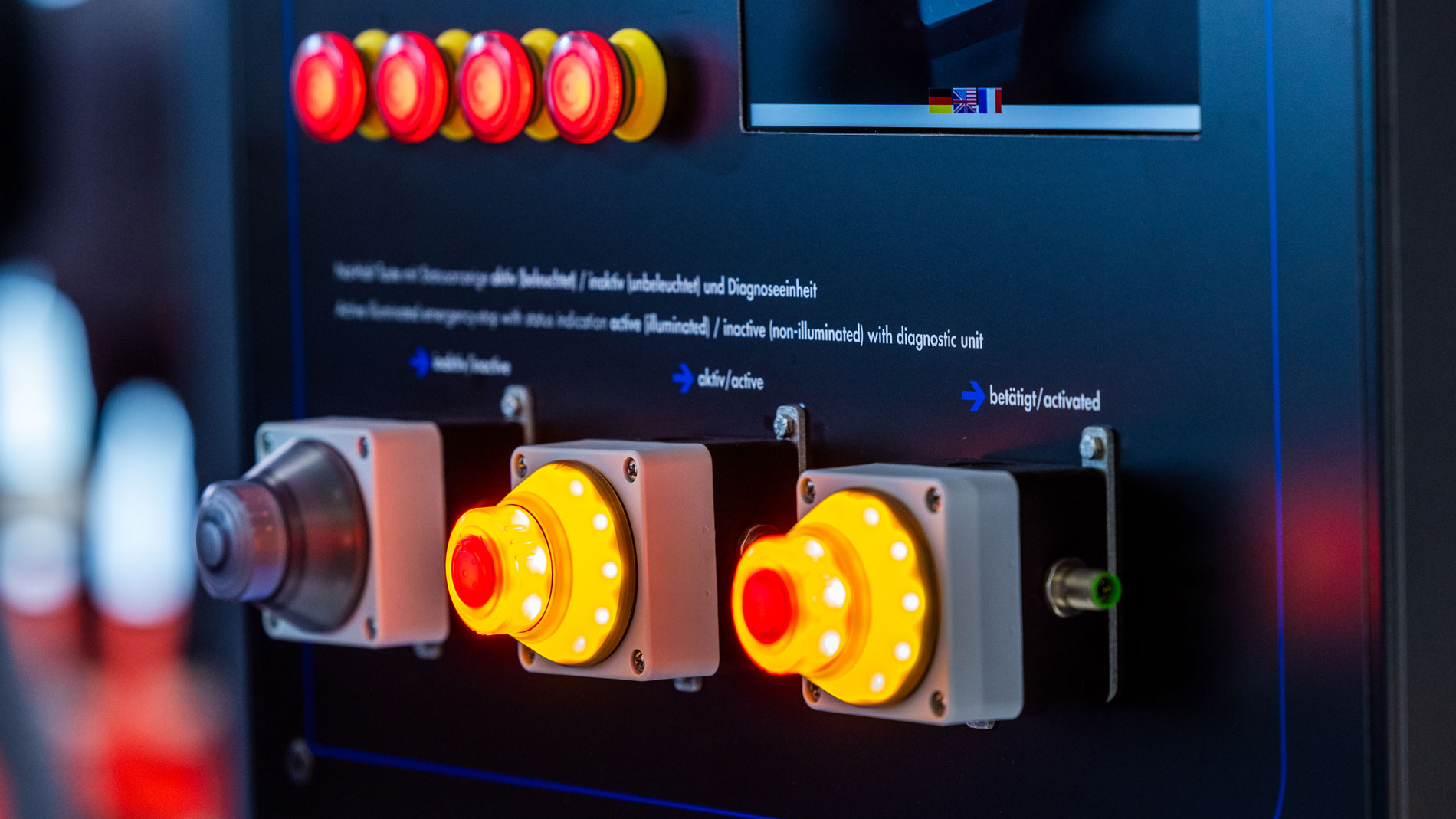

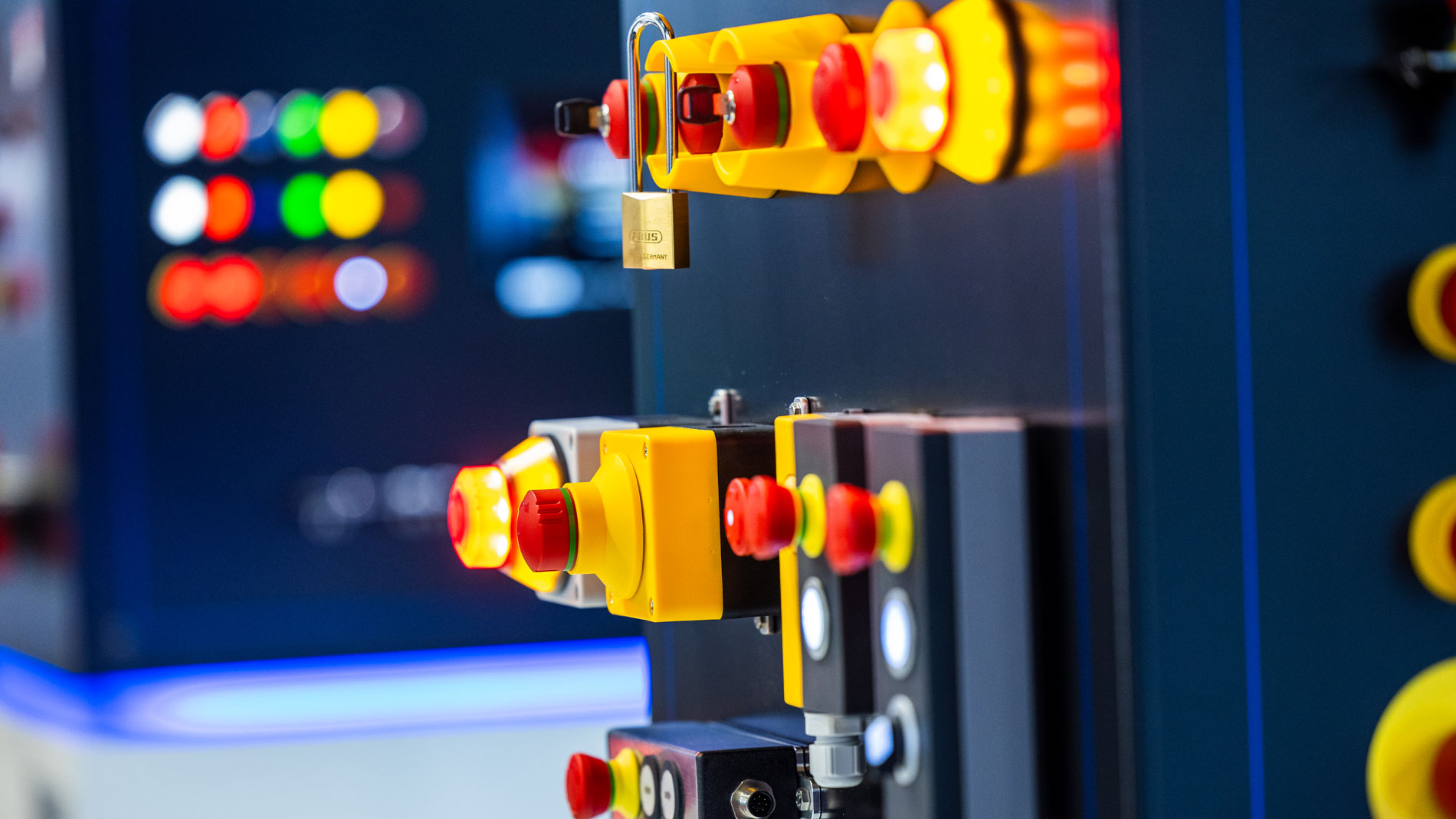

Human-machine-interface

A human-machine interface (HMI) in factory automation is the interface between operating personnel and automated systems. It enables the input of commands and the output of machine information. Typical forms include operator panels, touchscreens, keyboards, signal lights and mobile devices. Through the HMI, processes can be started, monitored and adjusted. Graphical user interfaces (GUIs) clearly display data and support fast decision-making. A good interface is characterized by user-friendliness, clear structure and responsiveness. Safety functions such as emergency stop or access rights are integrated. Modern HMI systems are networked and allow remote access via tablets, smartphones or cloud platforms. They make a significant contribution to the efficiency, transparency and flexibility of production and form the central communication bridge between human and machine.

Industrial communication

Industrial communication includes all technologies that enable reliable and fast exchange of information between machines, sensors, actuators and IT systems – often in real time. Key technologies include fieldbuses (e.g. Profibus, CANopen), Industrial Ethernet (e.g. Profinet, EtherCAT) and wireless communication (e.g. WLAN, 5G). It enables vertical integration from the shop floor to enterprise IT as well as horizontal networking between machines. Standardized protocols ensure interoperability between components from different manufacturers. Modern systems support Time-Sensitive Networking (TSN) for deterministic data transmission and meet high real-time requirements. Cybersecurity is essential, as networked systems are vulnerable to attacks. Communication technologies are constantly evolving – with higher bandwidths, lower latency and greater flexibility. Overall, industrial communication forms the backbone of intelligent and connected factory automation.