Tom Hammerbacher, Manager Digital Factory, Vertical Market Management Factory Automation, Phoenix Contact GmbH & Co. KG, Bad Pyrmont, Germany

In modern production, unplanned downtime is a costly disruptive factor. With MLnext Creation, Phoenix Contact provides a solution that enables domain experts to create powerful anomaly detection models without AI knowledge. The combination of MLnext Creation and MLnext Execution makes it possible to not only detect anomalies, but also to interpret them – a decisive step towards predictive maintenance.

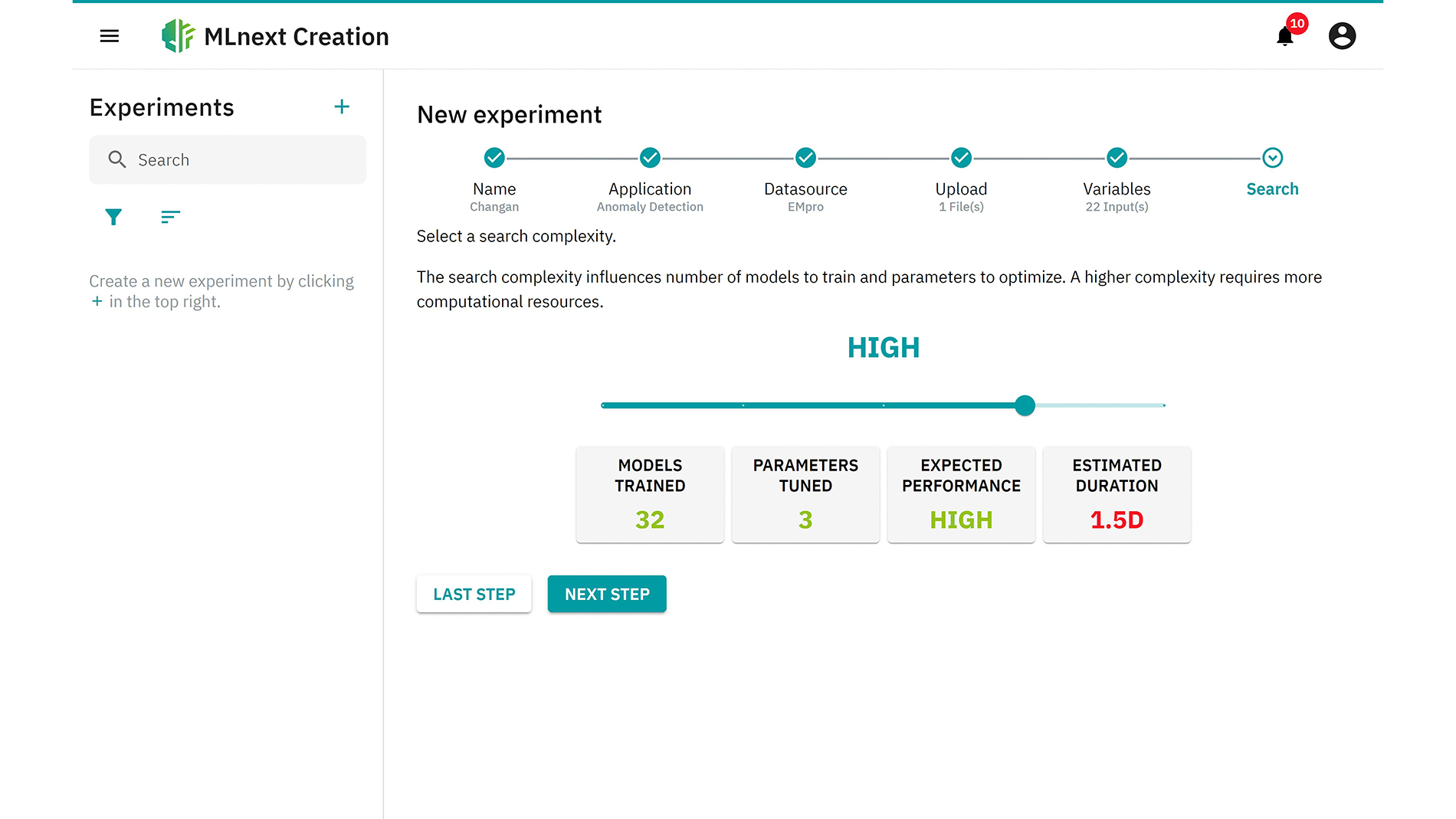

The machine learning solution begins with the selection of relevant data points. It is important that the corresponding sensor values or variables map the component to be monitored or the process to be analyzed. For example, power consumption, vibration, and temperature might be monitored for an electric motor. If there is a problem with the motor, this must also be reflected in a change in the sensor values. The fact that the type of anomaly in the sensor data can also be detected and interpreted by a human being is irrelevant. Furthermore, the expert does not need to mark these disruptions in the data. The models used in MLnext are able to detect atypical behavior solely based on deviations from normal behavior, taking the time sequence into account. If marked data is present, it can still be used to validate and improve the model. Once selected and recorded, the data can then be uploaded to MLnext Creation.

Interpretation of deviations

MLnext Creation is a software solution for creating machine learning models based on time series data. What makes it special is that the models are generated automatically, without requiring any programming knowledge. Users can configure experiments and train and compare models via a web interface. A key new feature is the interpretation of anomalies using Graph Deviation Networks (GDN) and Variational Autoencoders (VAE). These models allow deviations to not only be identified, but also localized to individual sensors and process steps. In addition, it is possible to see how the value deviates from the expected normal behavior. This turns a simple alert into interpretable information for the maintenance engineer.

The generated model can be downloaded as a file from MLnext Creation and applied to live data in MLnext Execution. To do this, Phoenix Contact relies on ONNX (Open Neural Network Exchange), the open exchange standard for machine learning solutions. This means that models from other machine learning solutions can also be used and managed in industrial applications with MLnext Execution. For example, the latest process data can be loaded directly from databases provided by Phoenix Contact for the PLCnext Control controllers. In addition, the data can be transferred via OPC UA, REST API, or a streaming processor. MLnext Execution then executes the models continuously or only when required. Production times are monitored and the results are made available. In this way, it is possible to ensure that the model’s response is available within the desired time for further processing. One such example is a conveyor belt that is controlled in different directions after quality control.

Preparation for server-client operation

MLnext Creation can be installed on PCs that use the Windows 11 operating system. A graphics card is not absolutely necessary for creating models for analyzing time series data. However, MLnext Creation can be extended easily with an existing and CUDA-capable Graphics Processing Unit (GPU). MLnext Execution can be installed as an app on PLCnext Control controllers and edge PCs from Phoenix Contact. This means that the machine learning model is executed directly where the data for automation is processed. This enables short response times, for example in combination with the OPC UA communication standard.

If a high degree of flexibility and scalability is required, the MLnext solutions can also be used as an OCI (Open Container Initiative) container. By implementing user interfaces as a web frontend and enabling operation via a REST API and user management, MLnext is ideally prepared for server-client operation. Phoenix Contact uses MLnext on its own deep learning server. This means that multiple specialist departments can use the MLnext services independently of one another. Furthermore, MLnext can be freely combined with other OCI container-based solutions from Phoenix Contact. For example, use in combination with Virtual PLCnext Control and the company’s IIoT apps provides an automation and analysis system. This provides significantly more options as an execution platform. Use in the central IT department on a server or in the cloud is also feasible.

Creation without programming knowledge

MLnext Creation bridges the gap between domain-specific knowledge and modern AI technology. The solution enables maintenance engineers and service technicians to independently create powerful models for anomaly detection – without any programming knowledge. When combined with MLnext Execution, the models can be used directly in production and provide interpretable information instead of mere alerts. This reduces unplanned downtime, optimizes processes, and sustainably increases system availability. MLnext is therefore a central component of a future-oriented, data-driven maintenance strategy.

About Phoenix Contact

Phoenix Contact offers innovative products, solutions, and digitalization expertise for the electrification, networking, and automation of all sectors of the economy and infrastructure. The family-run company empowers industry and society to transform into a sustainable world with long-term growth prospects for everyone – all driven by a passion for innovation and technology. Around 21,000 dedicated individuals around the globe work together with customers and business partners to drive forward these solutions for the energy revolution. Worldwide, Phoenix Contact manufactures products with varying levels of vertical integration in a production network. More than 50 international subsidiaries are part of the Phoenix Contact Group. In this way, the company is always close to its markets and customers. The integrated concepts, which include engineering and services, are applied in transportation infrastructure, e-mobility, for clean water, renewable energy and intelligent supply networks, and in energy-efficient machine building and systems manufacturing.

Efficient, safe, future-proof: With digitalization, modern automation and intelligent energy supply into the next generation of industrial production.