Get it wrong, and the consequences can be costly: cable jacket damage and premature failure, ingress and corrosion that undermine enclosure IP performance, or even intermittent communication/drive errors due to poor EMC bonding and screening.

As Craig Annal, Head of Product Development at one of the world’s largest cable gland manufacturers - CMP Products - explains, as much as a cable gland may seem like a small decision, it has a disproportionate impact on system reliability and lifecycle cost.

Craig said: “With many different cables available on the market, suitable for various applications, the precise gland selection underpins sealing and EMC integrity which ultimately safeguards connectivity in any junction box or enclosure, maintaining robust, interference-free operation. Having the right cable glands will ultimately maximise uptime.”

For more than 65 years, CMP has been helping engineers avoid these risks - partnering with customers early in the design phase to match gland types to cable constructions, environments, and EMC requirements ensuring safe, compliant and efficient installations every time.

TruSeal: Flexible by design for diverse applications

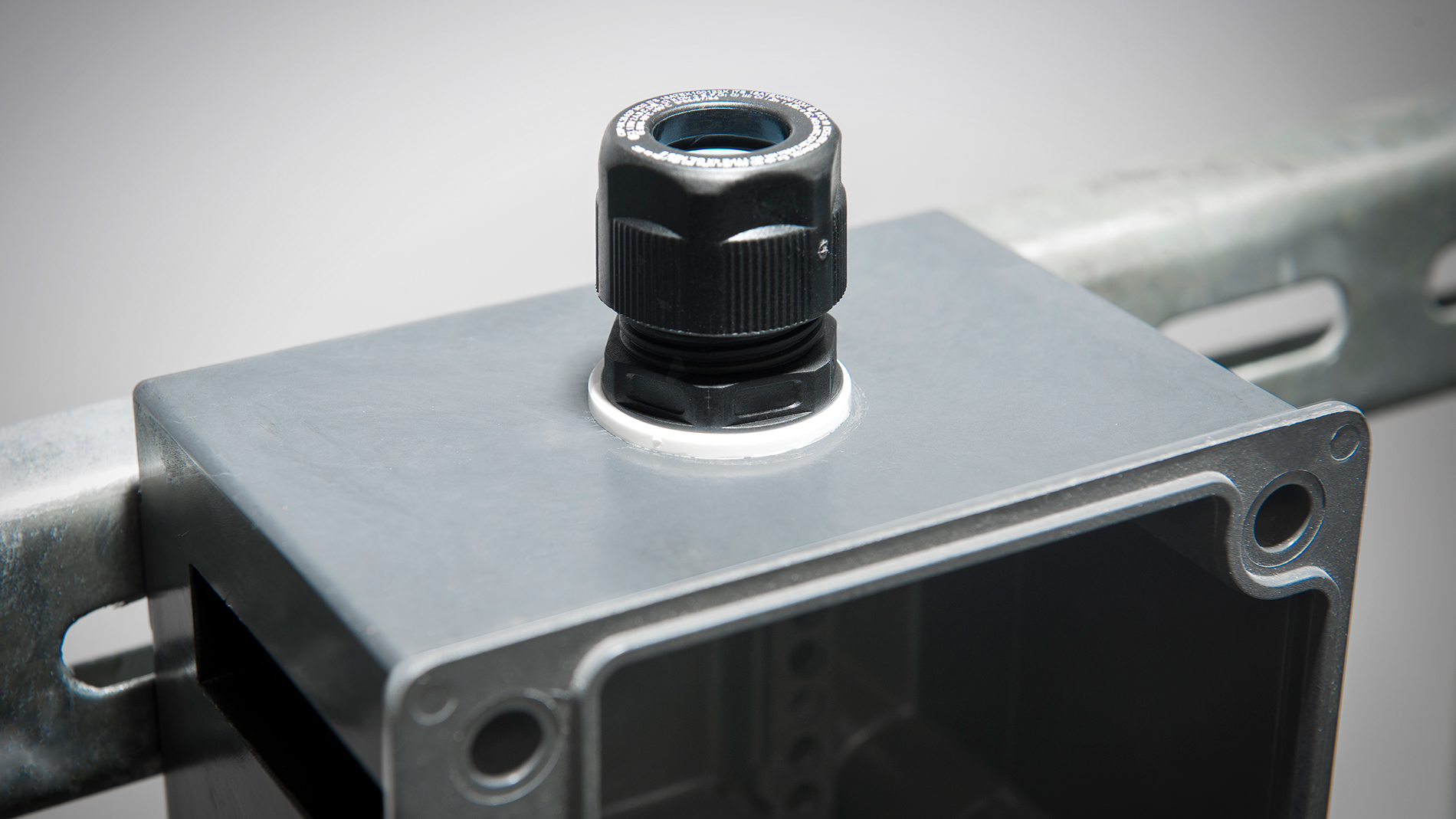

CMP’s flagship cable gland range, TruSeal - suitable for industrial and explosive atmospheres - is a standout choice across varied projects, thanks to its broad sealing capability over diverse cable diameters and constructions. This flexibility helps reduce part counts, simplify BOMs, and maintain performance across platform variants.

Since its launch in 2019, TruSeal has proven to be extremely popular globally with demand growing from OEMs, engineers and wholesalers across multiple industries and sectors due to the flexibility it provides for series production.

Proven Choice for OEMs and Automation

Offering ultimate flexibility, CMP’s TruSeal range is available in both polymer and metallic materials. The business reports it is seeing an increasing demand for its polymer range, due to it being an ideal solution for agile automation and OEM builds.

Polymer cable glands are the preferred choice when every gram matters, delivering performance benefits for weight sensitive axes and end of arm tooling while resisting corrosion and avoiding metal staining in hygienic or washdown environments. They also mitigate mixed metal corrosion risks on aluminium or plastic enclosures, providing a robust, non reactive interface.

Craig explains: “The polymer range is extremely lightweight, without compromising on the strength of the gland itself. For OEMs focused on cost and throughput, polymer solutions streamline assembly and help standardise components across high volume builds, improving consistency and reducing total cost of ownership.”

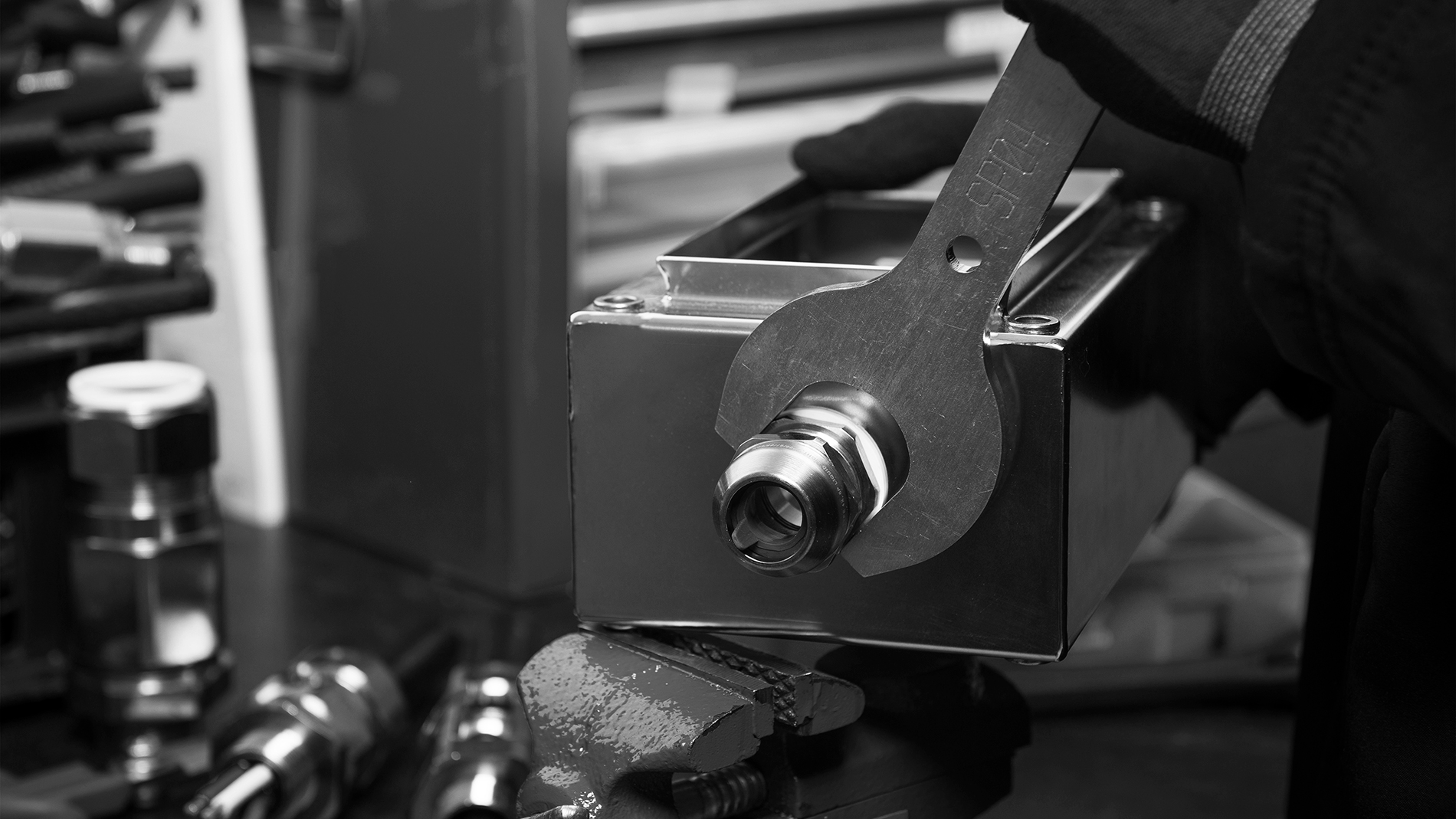

A fully compatible EMC range of TruSeal products is also available in metallic material, which is the ideal choice whenever there is a requirement for a reliable 360 degree low impedance termination of a braided or foil screen to maintain electromagnetic compatibility, typically for VFD/servo motors, robot axes, switching power supplies, industrial Ethernet, radio/IoT modules, and other high frequency or high speed signals where RFI/EMI must be contained.

Seal Configurations for Every Application

Selecting the right sealing method is critical to maintain ingress protection, strain relief, and long‑term reliability across varied cable constructions and environments. To help engineers match performance to application - whether space‑constrained control panels, trace‑heating terminations, or mixed cable size - the TruSeal range includes versatile, safety‑compliant options that cover standard, small, combined, flat form, and multi‑cable requirements.

Tested and Certified for Safety

Not all products are tested to the same standards. Some manufacturers perform only minimal testing to meet export laws. This approach is risky, which is why CMP mitigates risk by ensuring TruSeal not only complies with the prevailing safety standards for cable glands, but in many areas, even exceeds these requirements.

All TruSeal products comply, at a minimum, with IEC / EN 62444, while the explosive atmospheres products are tested and certified to IEC / EN 60079-0,7, 31. Each product undergoes CMP’s comprehensive testing program – including ageing, prolonged exposure to high and low temperature and humidity extremes, followed by cable retention, anchorage and twist tests, as well as cold impact and ingress protection testing, ensuring safety for personnel and protection of electrical systems throughout the product’s service life.

Engineered for Durability

The weight of larger cables should never be underestimated. If not properly restrained, a cable can pull out during service, causing significant damage to the equipment and costly downtime.

Using certified cable glands is the only way to ensure safe cable retention and protect electrical infrastructure. TruSeal glands can withstand the highest levels of impact in the market for this type of gland and maintain secure performance throughout their lifespan.

CMP certifies all cable glands to the IP tests in the standard IEC / EN 60529 and all are certified IP 66, 67, 68, 69 and 69K; ensuring they are suitable for harsh environments from an offshore deluge to industrial steam cleaning.

Sealing Range and Flexibility

Research conducted by CMP during product development found that one major competitor would need six glands to cover the same sealing range achieved by just two TruSeal glands.

For example, an M20 TruSeal cable gland would securely seal a 14mm, 9mm and even a 5mm cable. Its flexibility means it can accommodate cable tolerance variations - which are often ±10 per cent of the overall cable outer diameter - helping to prevent fit issues and ensure a consistent seal.

Beyond cable sizes, TruSeal offers adaptability in configuration and installation. All glands are available with standard or long metric threads, NPT options, and in six colour variants, simplifying selection for engineers and OEMs.

To protect enclosures during transport or before cables are fitted, CMP also supplies transit discs and Ex-certified IP plugs maintaining the rated protection level until final installation.

High-Performance Materials

Cable glands are often exposed to impact, heat, and UV light, which can weaken materials over time and compromise safety. To prevent this, CMP prioritised material selection in the design of the TruSeal range.

Many materials release harmful smoke or halogens when exposed to fire, posing risks to people and equipment. To mitigate such threats, the TruSeal range is manufactured from Low Smoke and Fume, zero Halogen and Phosphorus free (LSF0H) as standard. The Polyamide used is a tough, abrasion-resistant material that can be moulded at a low temperature, meaning less shrinkage and consistent quality.

Environmental exposure can also reduce product lifespan through cracking or degradation. CMP’s bespoke Polyamide blend meets the most stringent of IEC tests, withstanding seven joules of impact, offering one of the widest temperature ranges on the market and remaining UV-stable for long-term outdoor use.

Fire safety is another critical consideration in many installations. For applications requiring additional fire safety, a UL94 V0 flame retardant upgrade is available, ensuring any ignition self-extinguishes within 10 seconds on a vertical specimen.

Trusted Across Industries

Different industries place very different demands on connection components, from harsh outdoor environments to high-volume production. TruSeal’s flexibility goes beyond performance in the sectors it is suitable for. In a nutshell, there really isn’t an area it isn’t suitable for, from energy and power to data centres; transportation to Government projects.

Its broad sealing range and standardisation benefits have made it a popular choice among OEMs and wholesalers, helping them reduce stock levels while enjoying a high product turnover.

Complete Confidence with TruSeal

From specification to installation, TruSeal gives engineers complete confidence. Designed, tested and manufactured in‑house by CMP, the range combines broad sealing capability, polymer and metallic variants - including fully compatible EMC options - LSF0H materials with optional increased flame retardant UL94 V‑0 variants, and market‑leading ingress protection (IP66/67/68/69/69K).

By reducing part counts, simplifying BOMs and stocking, and de‑risking compliance with IEC/EN 62444 and IEC / EN 60079‑0,7, 31, TruSeal helps OEMs and operators accelerate build, cut lifecycle costs and safeguard uptime across many industries.

In short, smart automation starts with reliable connections - and with TruSeal, those connections are built to last.

To find out more visit: https://cmp-tv-TruSeal.urdev.co.uk/cmp-TruSeal.html

About CMP

CMP is a market-leading specialist designer, manufacturer and supplier of cable glands, cleats, lugs and accessories. Established in 1957 as part of the British Engines group, the company ensures that customers remain at the heart of everything it does, wherever they are in the world.

CMP sets the standards for quality and service and leads the way in product innovation, while maintaining integrity, safety and reliability. Whether its products are used for onshore or offshore oil and gas installations, power generation, transportation infrastructure, or surface and underground mining applications, they are engineered to protect the safety of people and organisations.

By remaining focused on this commitment to customers, CMP has grown to become a world leader in its market, continuing to provide assurance of the highest standards of quality and service.