Drive systems consisting of motors, gear units and drive electronics, as well as their performance, significantly contribute to the availability and efficiency of production plants. With NORD DRIVESYSTEMS’ data-based approach, users can optimally align drive solutions in every life cycle phase.

The planning phase – Virtual commissioning saves time and minimises errors

Simulation models have already found their way into machine and system planning. In 2010, the publication of the technical standard FMI (Functional Mock-up Interface) formed the basis for the increasing model data exchange across projects. Virtual commissioning of entire plants became possible.

“The advantage of virtual commissioning lies in the significantly faster availability of the entire plant. It significantly shortens the overall process up to commissioning and ensures that even plants with complex drive systems are ready for operation more quickly.”

Marcus Jensen, Head of Corporate Communication & Marketing Intelligence, NORD DRIVESYSTEMS

NORD will provide configured drive systems as simulation models in future. Registered myNORD users can request the digital twin for their configured drive systems or components. The digital twin configurations are integrated into a simulated system where they can be extensively tested. NORD will first enable virtual commissioning for its portfolio of highly efficient IE5+ and IE4 motors and the associated gear units and frequency inverters. Simulation models will then gradually become available for other NORD product areas.

This offers several advantages to designers and planners:

- Less risk: Errors can be remedied in the early stages of development, avoiding potential later damage.

- Customisation for optimum fit: Based on the data, the configuration can be easily adjusted several times. NORD will start the manufacturing process only after the customer has validated the virtual system.

- Fast commissioning: Actual commissioning takes place quickly as the drives have already been functionally integrated into the system control.

- Short time to market: Systems are quickly available even with complex drive systems. The overall process from configuration to commissioning is reduced from several months to only a few weeks.

The operational phase – Reducing the total cost of ownership

“We often come upon oversized drive systems. The measurements of our NORD ECO service reveal this and provide data for alternatives. This usually achieves lower TCO.”

Jörg Niermann, Marketing Director, NORD DRIVESYSTEMS

Even in existing systems, the drive systems’ performance can be regularly reviewed. Is the energy consumption still the most efficient one to be achieved? Are there new target values to be achieved with regard to CO2 equivalents? With the NORD ECO service, the drive technology’s consumption data in an installed system can be made transparent and, if required, alternative solutions explored.

The NORD ECO box is an auxiliary tool, connected between the motor and the installation’s power supply. It consists of an energy measuring device with data logger function, current transformer and cable connections. For at least two weeks, the NORD ECO box records permanent loads, load peaks and irregular conditions. This shows whether a system’s dimensioning corresponds to the requirements of the respective application. Upon completion of the measurement, NORD evaluates the data via its own software. Based on this, the company prepares a proposal to optimise the system performance, increase energy efficiency and potentially reduce the number of used component variants. The installation of this alternative system is followed by a comparative measurement with a final analysis. The NORD ECO process usually achieves lower energy consumption with reduced CO2 emissions and lower TCO (total cost of ownership).

NORD could thus reveal significant savings potential in customer applications, and use them with alternative solutions. Here are two examples from airport baggage systems:

- Energy savings of up to 50% plus less variants: The IE1 motors in different baggage handling systems have been replaced by a DuoDrive solution from NORD with IE5+ motor. It consumed up to 48% less energy. In individual cases, NORD’s calculation revealed that thanks to the integrated DuoDrive gear unit/motor concept up to 50% less drive variants might be required. The highly efficient NORD motors achieve a constant torque over a wide speed range and are thus particularly suitable for the reduction of variants.

- Upgrade of the already high energy efficiency: For an already energy-efficient drive concept with IE3 motor, NORD ECO established the option of additional energy savings of about 20%. This was implemented by a DuoDrive solution with IE5+ motor and a decentralised NORDAC frequency inverter. After a comparative measurement of both systems over a period of a little more than a year, it was possible to finally determine a savings potential of 590 kWh.

The maintenance phase – Avoiding unscheduled downtimes

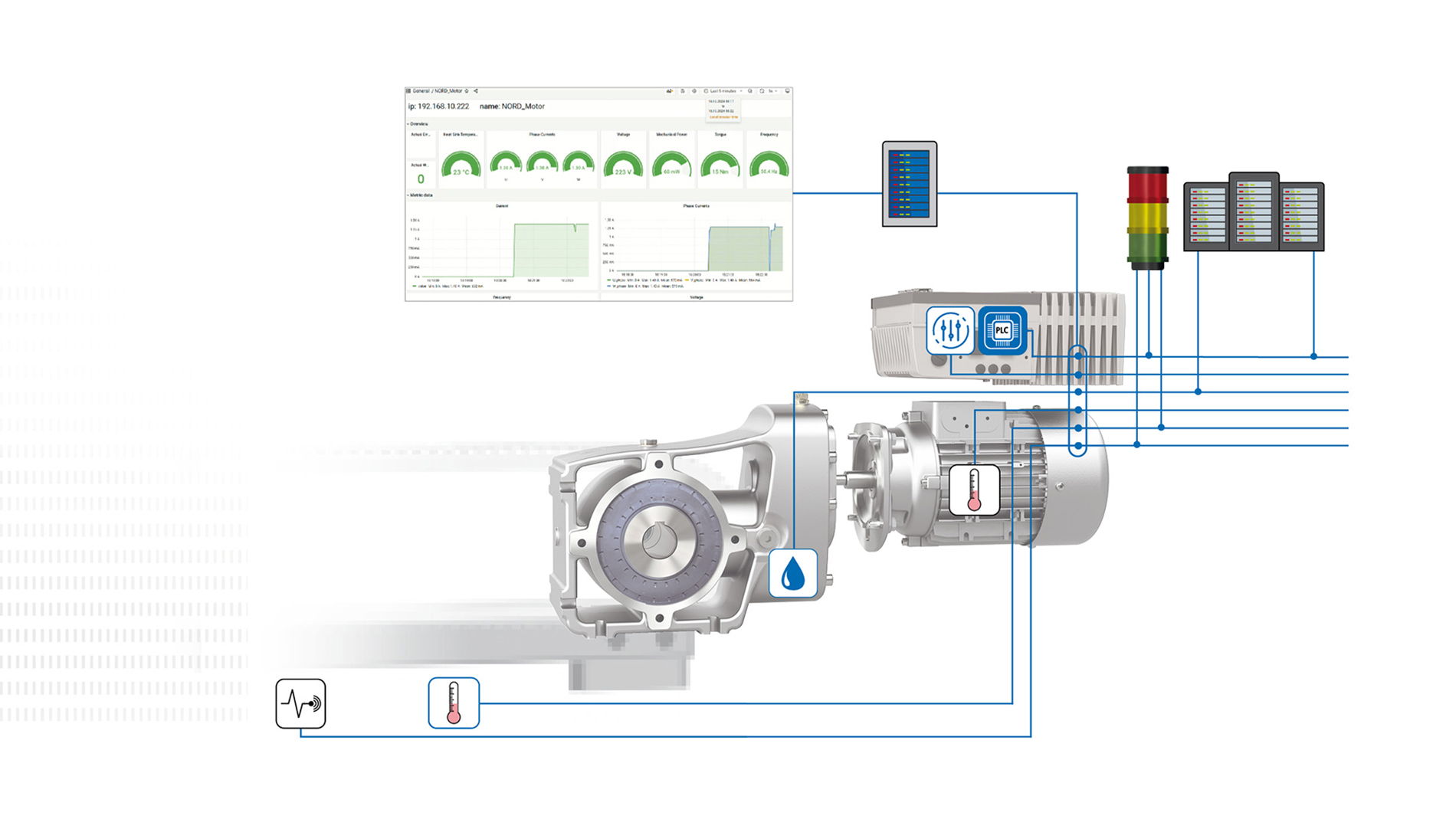

The operating data of a drive solution also permanently provides information on the current state of the components. Within the IIoT, the operating data is available to a higher-level control level, which uses it in condition monitoring for predictive maintenance.

“NORD drive electronics provide the data for condition monitoring, which serves as the basis for predictive maintenance. Over the data bus of the NORD DRIVE MONITOR, this data can be transferred from other applications and processed.”

Dirk Boysen, Sales Director Electronic Drivesystems, NORD DRIVESYSTEMS

With its IIoT solution DRIVE MONITOR, NORD provides dynamically calculated and sensor-captured operating values of its electronic drive systems for further processing. Users can thus identify any anomalies or wear at an early stage, and plan maintenance measures. This not only allows proactive maintenance of machines and systems. Downtimes are reduced effectively, and the service life of machines and systems as well as the overall system efficiency are increased.

How does DRIVE MONITOR work? The IIoT solution from NORD obtains drive parameter values from the drive systems. Since all NORD frequency inverters are equipped with an integrated PLC, they can evaluate drive and sensor data, such as vibration, based on threshold values. The drive electronics make the determined data available via a data bus. The architecture of the data bus and the formatting of the data comply with current industry standards. By means of standard technologies such as MQTT or TimescaleDB, DRIVE MONITOR can integrate its data into higher-level systems. The visualisation on a dashboard takes place via Grafana. The NORD solution’s architecture is furthermore modular and scalable. It can thus be adjusted to the respective system size. Provided in docker containers, DRIVE MONITOR can be used in any IT infrastructure.

Image: Getriebebau NORD GmbH & Co. KG

An evaluation example is the optimum time for an oil change (currently available as an optional function for 2-stage helical bevel gear units):

- Algorithm calculates the change: NORD’s calculation of the optimum oil change time is based on the fact that the oil temperature is a key factor for oil ageing.

- Elimination of physical temperature sensors: By means of various drive-specific and operational parameters, the NORD solution can continuously calculate the current oil temperature using virtual sensors.

- Frequency inverters acting as data collectors and analysts: The algorithm is executed in the integrated PLC of the installed frequency inverter. The latter is thus the evaluation unit where thresholds are pre-processed.

Holistic digitalisation

All digital solutions must focus on the benefit for value creation. For this purpose, NORD collaborates with partners, for example in the field of virtual commissioning with the software company Machineering from Munich. This way, the solution provider for drive systems can provide the digital services, which meet the critical market demands: Their tailor-made data evaluation shortens process times, optimises the efficiency of machines and systems, and consistently reduces costs.

About Getriebebau NORD

With approx. 4,800 employees today, NORD DRIVESYSTEMS has developed, produced and sold drive technology since 1965, and is one of the leading global full-service providers in the industry. In addition to standard drives, NORD delivers application-specific concepts and solutions for special requirements such as energy-saving drives or explosion-protected systems. In the 2023 financial year, annual sales amounted to € 1.09 billion. NORD has 48 subsidiaries in 36 countries and further sales partners in more than 50 countries. They provide technical support, local stocks, assembly centres and customer service. NORD develops and produces a wide range of drive solutions for more than 100 industries, gear units for torques from 10 Nm up to over 282 kNm, supplies electric motors in the power range of 0.12 kW to 1,000 kW, and manufactures the required power electronics with frequency inverters of up to 160 kW. Inverter solutions are available for conventional control cabinet installations as well as for decentralised, fully integrated drive units.