It pays off to be prepared – find out about all exhibiting companies and the entire product range that will be presented at the SPS this year. This will help you to get in touch with the right business partners.

Here you can find the exhibitors at the SPS 2025. This online search gives you an overview of the participating companies and will be updated regularly.

Use the various filter functions to search for specific product groups, halls, contact information and much more. The filters can also be combined with each other in any way, so that you can adapt the search to your individual criteria.

Exhibitor search SPS 2025

DYNETICS GmbH

The world's smallest servo motor of all hollow shaft types:

Explore product

gLESS non-contact magnetic counterbalance

Explore product

The world's smallest servo motor of all hollow shaft types:

Explore product

gLESS non-contact magnetic counterbalance

Explore product

The world's smallest servo motor of all hollow shaft types:

Explore product

gLESS non-contact magnetic counterbalance

Explore productAbout us

Dynetics, founded in 1994, with offices in Germany and the Netherlands assists engineers in selecting the best suitable motor for their mechatronical assignment.

Dynetics represents leading manufacturers such as Nippon Pulse Motor (NPM), Nidec, KSS, Synapticon, TPM, etc. Our European central warehoiuse is located in the Netherlands (Best)

We offer a wide range of small motors and actuators with various technologyies

Dynetics helps economizing your design by offering linear and rotating solutions with optimum price-perfomance ratio. Many of products can be "customized"

For equipment cooling we have a variety of axial instrument ventilators and radial blowers

For more details, please visit our website: www.dynetics.eu

Keywords

- linear solutions

- rotating solutions

- fans & blowers

- electronic driver & controllers

- Customized Mechatronic solutions

Our Products

The world's smallest servo motor of all hollow shaft types:

The world's smallest servo motor of all hollow shaft types:

The servo motors of the MDD family (Micro-direct-Drive) are available in dimensions from 13 mm to 70 mm and with 3 lengths. They offer speed and precision in a compact design that allows for adaptability to the unique requirements of the application. The MDD motors consume less power than other motors with the same power and service life. Due to the special windings, the use of strong ball bearings and extra strong magnets, this motor in a compact housing makes a robust motor with a very high torque (up to 1000 mNm, with peak values up to 3100 mNm)

The MDD motors work with alternating current (AC), which provides high starting torque.

The overwhelming high rigidity, high speed and high accuracy of MDD motors is achieved thanks to the design of the motor, where the shaft is directly connected to the gearbox.

For the realization of precise positioning, the motors have an integrated encoder (absolute or incremental) with high resolution. On request, the MDD series can be supplied with a hollow axis, and customer-specific adaptations (e.g. special seals) are possible. These robust and space-saving motors are extremely precise and are used in a wide range of direct drive applications where precise positioning, along with power, is required

MDD motors offer high performance in a compact and lightweight package for robotics applications. Examples include not only high-precision devices in cleanrooms such as Scara, pharmaceutical robots and small gantry, but also in industrial robotic arms such as for cobots, articulated robots for production plants with complex assembly work in harsh conditions, and precision machines such as SMA devices for electrical and semiconductor manufacturing

ACTILINK; the complete and cost effective integrated Servomotor for high dynamic applications

For industrial applications like advanced machinery and robotics, Dynetics offers several types of rotating and linear motors, including servo, stepper, brushless DC, and brushed DC motors.

ACTILINK, the all in one Servo drive for precision control

The new ACTILINK family of integrated servo motors replaces multiple parts and functions in a servo axis and available with 5 basic models, to cover a power range to 1000W and a torque level to 3,2Nm

Advantage of integrated Servomotors:

The customer is receiving a complete wired and tested motor set (motor, encoder, safety and driver) shortening his test procedure and realize a faster integration compared to conventional system.

By keeping the electronics on the backside of the motor, the supplier realized with ACTILINK the most compact solution of a complete integrated motor,

The unit utilizes MPD-Control technology from Synapticon completed with extra low voltage technology for unparalleled efficiency for a Permanent operation at maximum motor temperature (>140° C)

Features:

- 13+ safety functions, to prevent undesirable motion

- high-resolution battery-free multiturn

- encoder, integrated power and EMC

- management, common DC link for maximum efficiency

- EtherCAT / PROFINET / EtherNet/IP / CAN

- Hybrid single cable technology replaces 3 cables with one

- A led-ring indicator to display the status of the motor

Service friendly and cost effective:

A further big advantage of the ACTILINK-S family of integrated servo motors is that the motor and driver can be separated for services; many other integrated motors are fixed as one final unit and can’t be exchanged as individual part.

Controlling:

An external PC can be used as Machine Level Controller, but ACTILINK can also operate decentral, by the user friendly Python script code format.

During operation, you keep access to all motion objects and parameters through the script, communicated through the IO’s of each motor

The connection to the motor are standard ISO- or Hybrid-connectors

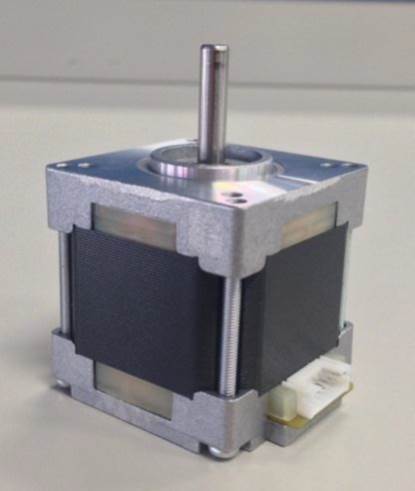

the KV42 and KF42 Hybrid stepper motors show a more compact size

Nidec Advanced Motors introduced their new Nema17 sized bipolar (Flange=42mm) stepper motor family under the product code KV42 and KF42.

With the KV42 and KF42 Nidec (represented by Dynetics) has increased their family of Hybrid-stepper motors with an angle of step of 1,8°. Thanks to the optimized design of the rotor, the supplier managed to realize a more compact size of the motor. Compared with equivalent type of stepper motors in the industry, both families of the improved stepper motors enable them to realize a much higher performance within a more compact housing. Instead of the previous length of 48 mm these motors only show a length of 42 mm. The motors with previous length of 42mm are reduced to 39mm, etc.The KF42 even realizes a higher torque-level. Further advantages are:

- Higher maximum torque

- Higher stall torque

- Higher speed

- Minimum level of noise

- Precision windings, outstanding stiffness

- Improved dynamics

- 5 different size

With these upgrades, the stepper motor family KV42 and KF42 show the highest level of power density in their class. The motors are available with connector or free cable ends. At customers request the supplier also accepts different mechanical upgrades.

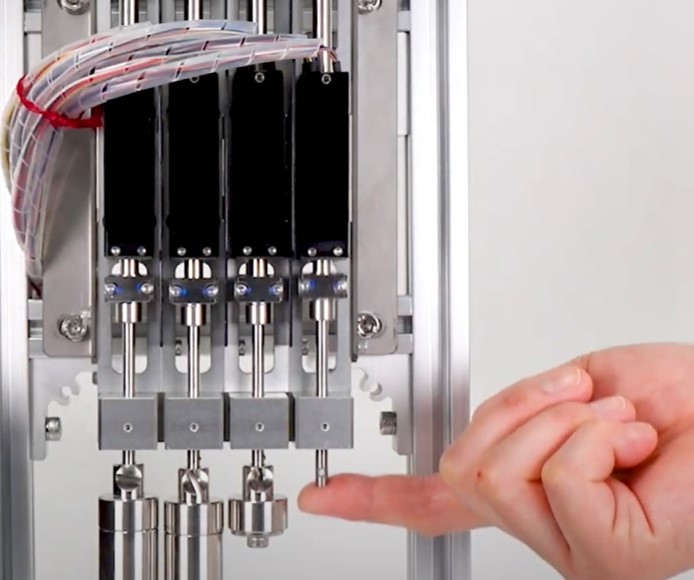

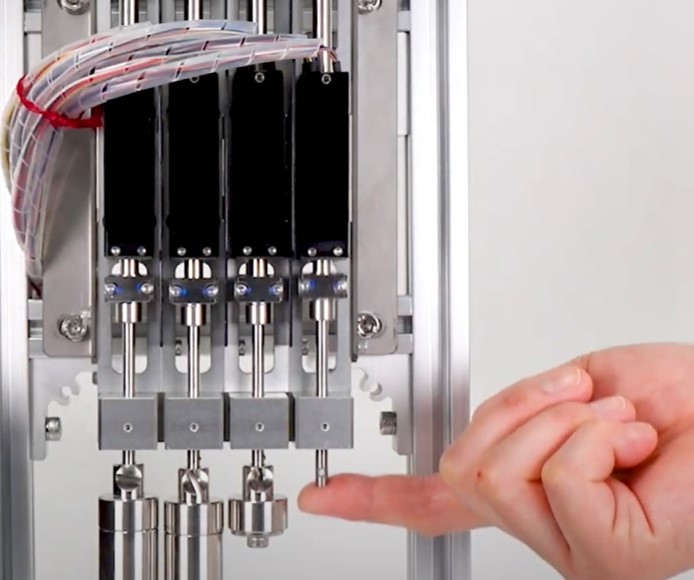

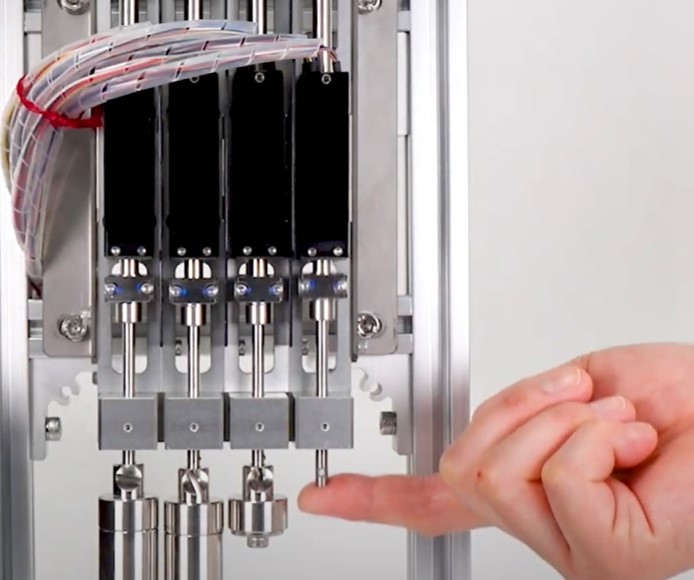

gLESS non-contact magnetic counterbalance

When shaft motors are used vertically, a counterbalance is required to cancel out gravity. If there is no balancer, the motor will fall if it is not energized.

"gLESS" is a new type of counterbalance that uses magnetic force.

The counterbalance is realizing a stable movement and is maintenance-free Compared to the spring type, it has the following features and advantages.

- The constant does not change even after many years of use

- Does not fall even if the motor power is cut off

- There is (almost) no leakage of magnetic flux

- Unit design with shaft motor can be compacted

- Balance force is constant

- Since it is contact-free, it is highly clean and maintenance-free

In the previous design, the spring counterweight was a critical component, as the spring ages over time and requires extra attention for maintenance.

This new counterweight is called "gLESS", and is a non-contact solution that can be mounted very close to the shaft motor. This creates a very compact unit for the Z-axis.

The gLess series is available in 3 versions reaching the forces 2,66; 6,1, and 19,6N and an effective stroke of 40mm

This is an ideal shape as a balancer on the vertical axis. The new family of integrated linear shaft motors has been specially developed for the realization of the vertical Z-function and features high-energy magnets for more power in the mid-range combined with a very compact and efficient counterweight (patent pending). The motor unit does not fall off when de-energized, thanks to its new and revolutionary solution for the desired counterweight.

NPM introduced a new complete linear motor unit, based on the scaleless linear shaft motor SX060 series completed with this gLESS counterbalance. The linear motor doesn’t need an external encoder, and has almost no magnetic leakage fluxes, which allows compact applications of more than one motor with a distance between of only 9mm.

The linear servo motor does not need to be lubricated and has no power losses due to wear/aging. Its maintenance-free, long service life contributes to a lifelong cost reduction and this new linear shaft motor unit maintains a constant balance at all times of the stroke

You can check out the functionality of this reference design via Youtube:

- Pipette Chidori project: (https://youtu.be/JGIOjzdX3lQ)

- gLESS counterbalance: https://www.youtube.com/watch?v=Zl6tVf4Gtho

Miniature Ball Screws with ISO (DIN) Standard

KSS is a manufacturer of ball screws and actuators, especially for miniature sizes with a shaft diameter of 16 mm or less. KSS designs, develops and manufactures miniature ball screws, miniature actuators and their related products, with a focus on miniature size.

KSS Miniature Ball Screws or Actuators are used for semiconductor or liquid crystal production machinery, inspection equipment and machine tools, etc. Recently, KSS has expanded its use for medical equipment, robots, food machinery, injection molding machines, aerospace and automotive.

The production range for coolant ball screws ranges from φ1.8 to φ16 mm as nominal shaft diameter. The maximum limit of the total lengths depends on the configuration of the shaft end, the materials and the coolant series. The accuracy of the ball screws complies with JIS B 1192-3 and is specified by the tolerance for the specified travel over the effective travel of the nut or the usable travel of the screw shaft, the travel variation and the travel deviation within any 300 mm and 1 revolution (2π rad) over the usable travel of the screw shaft.

What is new is that they also comply with the ISO standard (ISO 3408-2 Series1 / DIN 69051-5)The new series is called "NSG" and complies with the ISO/DIN standard. Ball screws with outer diameter of nut according to ISO standard (ISO 3408-2 Series1 / DIN 69051-5) Reinforced circulation device and optimized ball circulation improve rotational performance reliability and durability. The ball screws were developed with the SDGs in mind. The M-threaded nuts are standardized and adhesive-free to reduce disposal losses