The exhibitors of the SPS 2026 are expected to be published in spring 2026. Until then, you can find the exhibitors and products of the SPS 2025 here.

Exhibitor search 2025

Description

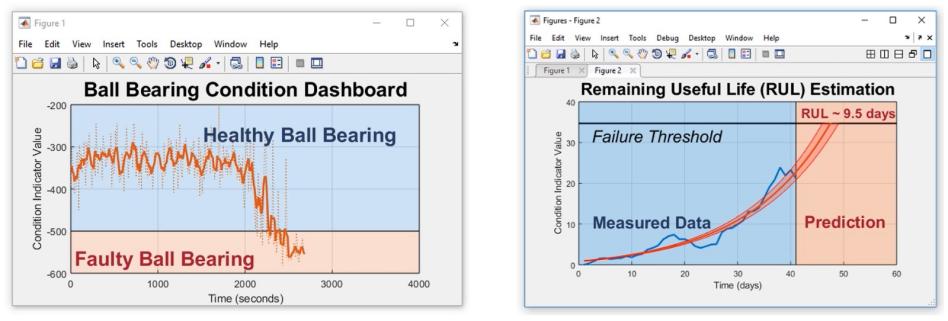

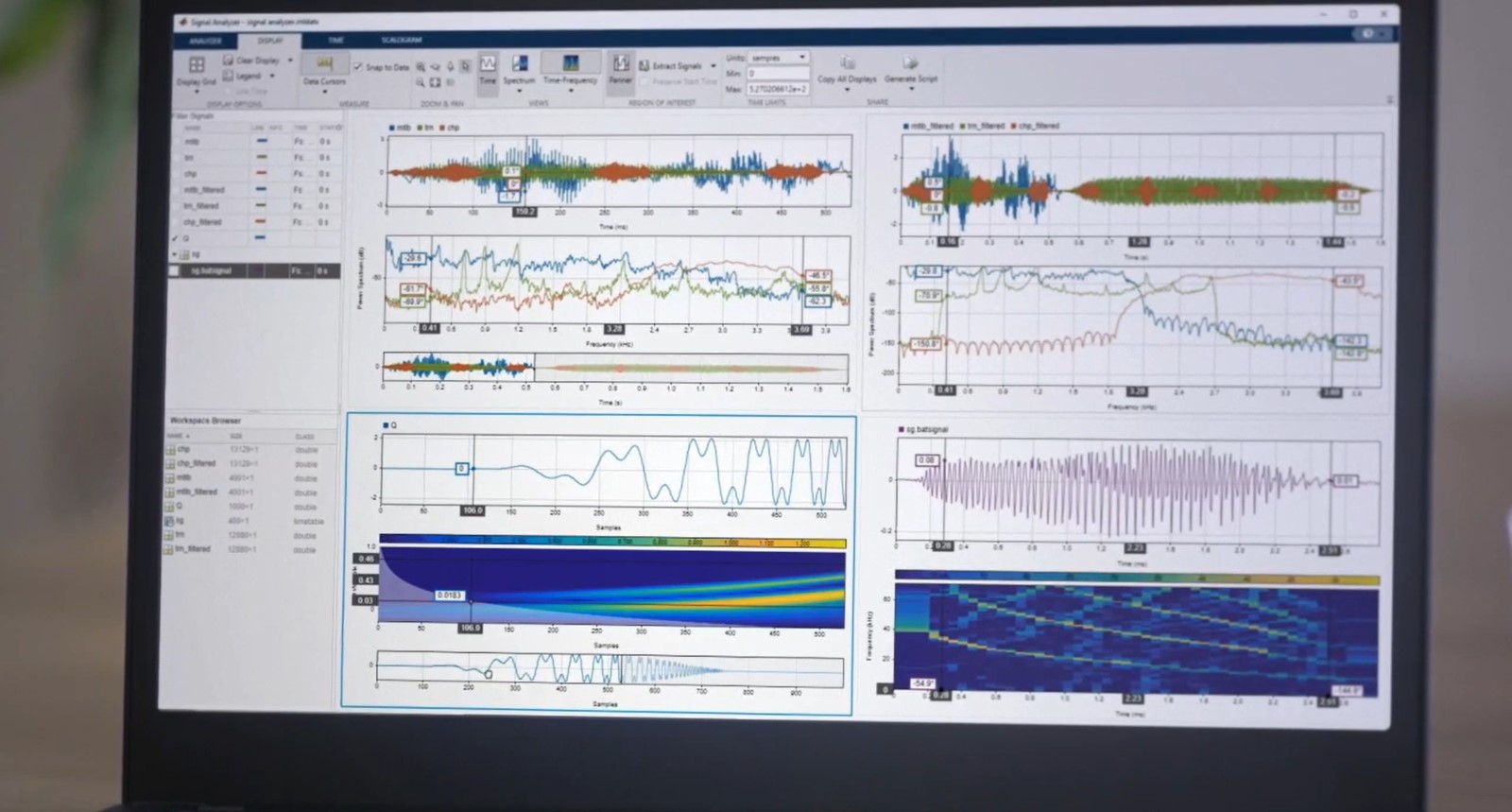

Predictive Maintenance Toolbox™ lets you manage sensor data, design condition indicators, and estimate the remaining useful life (RUL) of a machine.

The toolbox provides functions and an interactive app for exploring, extracting, and ranking features using data-based and model-based techniques, including statistical, spectral, and time-series analysis. You can monitor the health of batteries, motors, gearboxes, and other machines by extracting features from sensor data. To estimate a machine's time to failure, you can use survival, similarity, and trend-based models to predict the RUL.

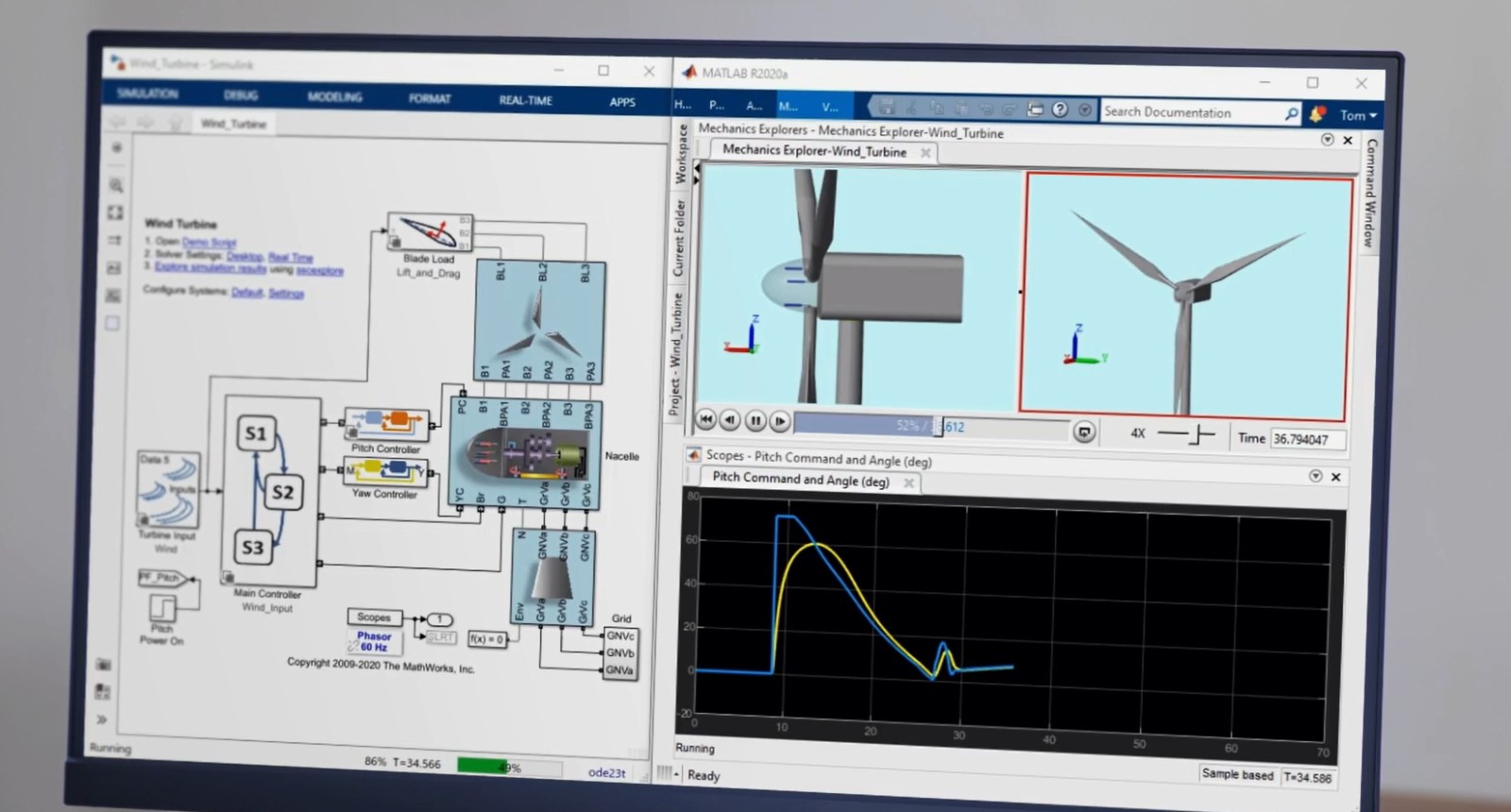

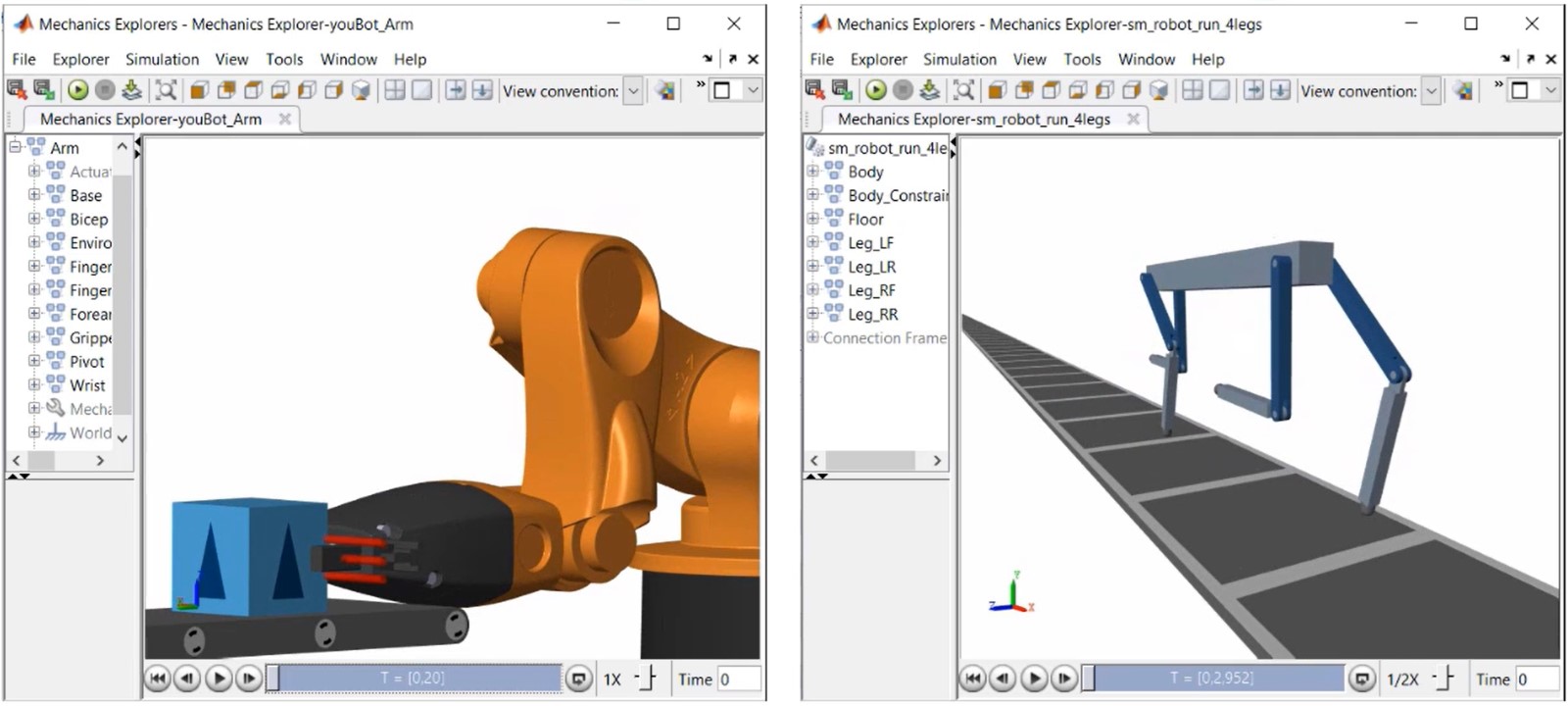

You can organize and analyze sensor data imported from local files, cloud storage, and distributed file systems. You can label simulated failure data generated from Simulink models. The toolbox includes reference examples for motors, gearboxes, batteries, pumps, bearings, and other machines that can be reused for developing custom predictive maintenance and condition monitoring algorithms.

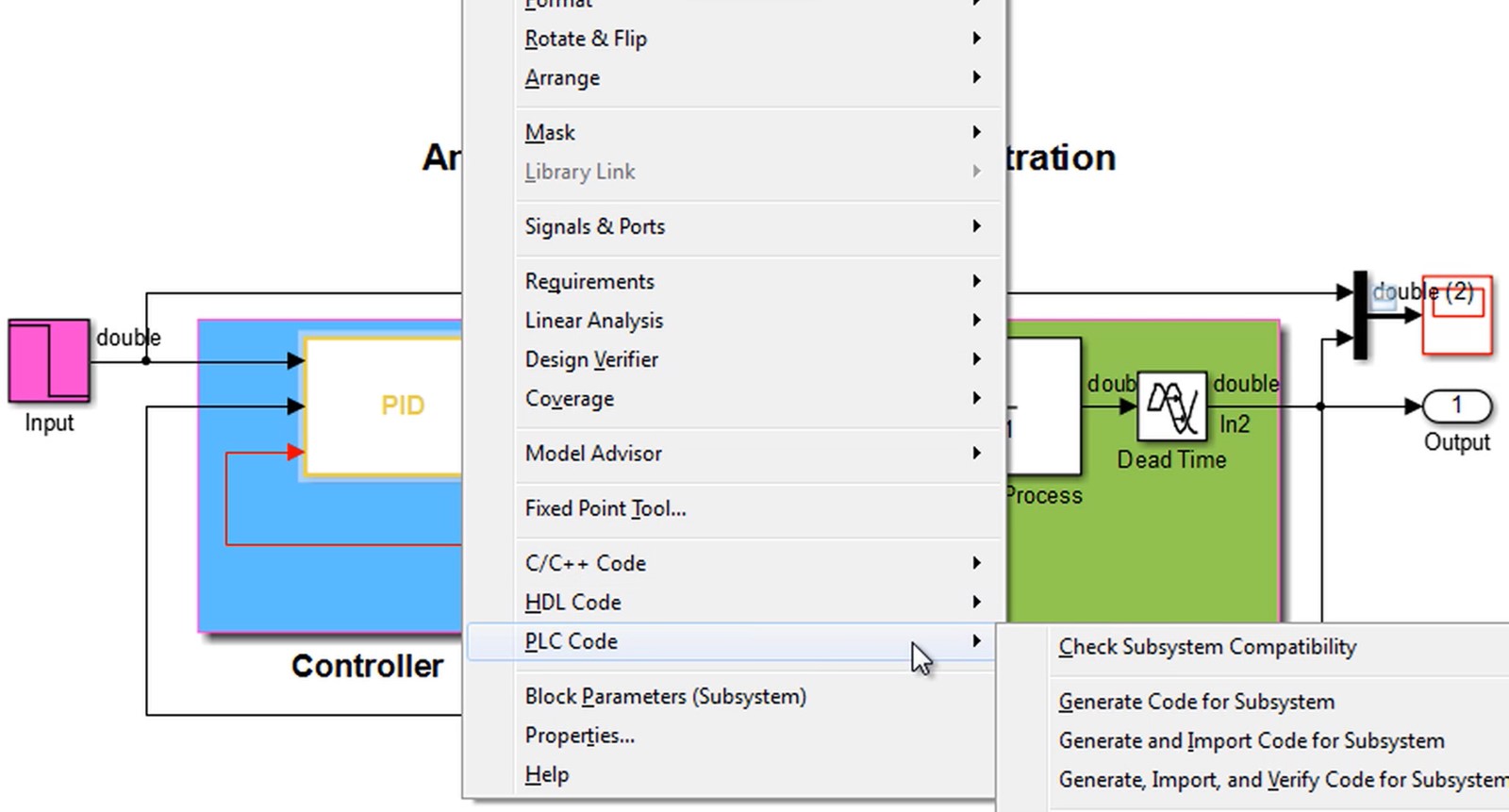

To operationalize your algorithms, you can generate C/C++ code for deployment to the edge or create a production application for deployment to the cloud.