Industrial Operation Panel - Arm-Mounted Panel PCs

Industrial Operation Panel - Arm-Mounted Panel PCs

Description

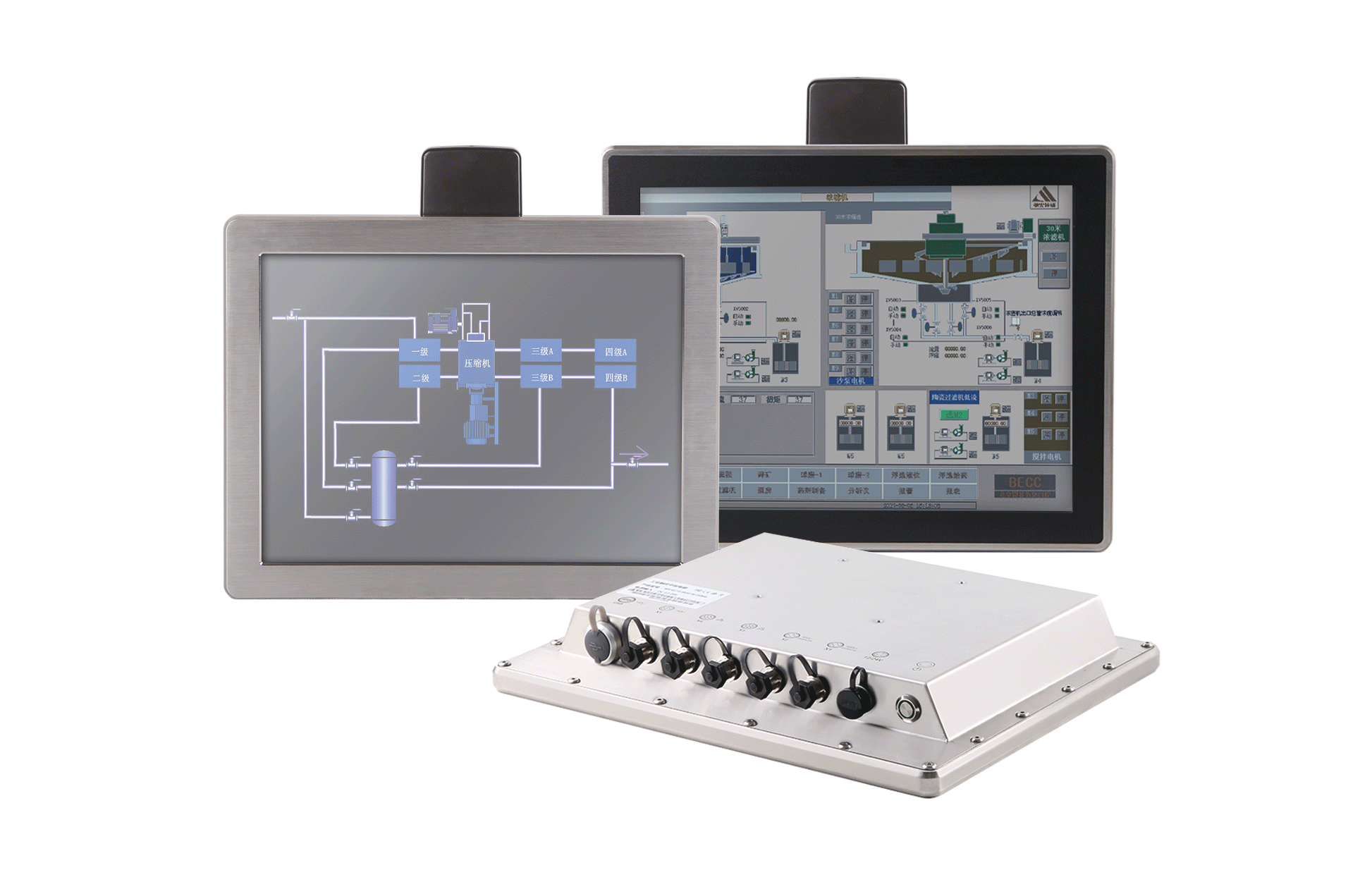

Arm-mounted Panel PC HMI featured a full IP65-rated enclosure for maximum protection and a wide array of customizable button options to enhance functionality for automation operation panel applications, integrated with RAFI® BUTTON and Rittal® CP40 Swing ARM, support 7th Generation Intel® Core™ i5.

Nodka Industrial Operation Panel offers robust and versatile solutions for industrial automation environments. The latest version of Operation Panel is a highly-integrated and stylish design with user-defined function RAFI® BUTTON for interchangeable colored lenses and various switch types, enhancing functionality and user interaction. Those key switches and an integrated E-stop button provide exceptional user-friendly functional experience during operation.

The latest Operation Panel, integrated with UPS, equips with a wide range of connectors. It can be widely used in all kinds of machine tools, such as automobile manufacturing, petrochemical, food, pharmaceutical machinery and other automatic equipment, testing equipment and human-computer interaction equipment.

Industrial Operation Panels are available either with a projected capacitive touch screen monitor (IDP59 series) or with additional PC system (ICP69 series).

ICP69 series support NODKA COMLAC INSIDE design. Interfaces has option 2 Intel gigabit RJ45 ports, 4 USB and 2 RS232/485 ports.

Size: 15", 18.5", 19", and 21.5"

Touchscreen type: Capacitive Touch Screen

CPU option: Intel® Core™ i5-7200U, Intel® Celeron® Processor J1900

Features

- Modular design, NEMA4 Aluminium Chassis, support NODKA COMLAC INSIDE design

- Full IP65, Fanless design. Suitable for industrial use.

- User-defined RAFI® BUTTON. Customized buttons are possible in small batch production

- Support Rittal® CP40 Swing ARM. Different mounting options are possible.

- Wide Work Temperature range, operation temperature from -20 up to +60°C