Description

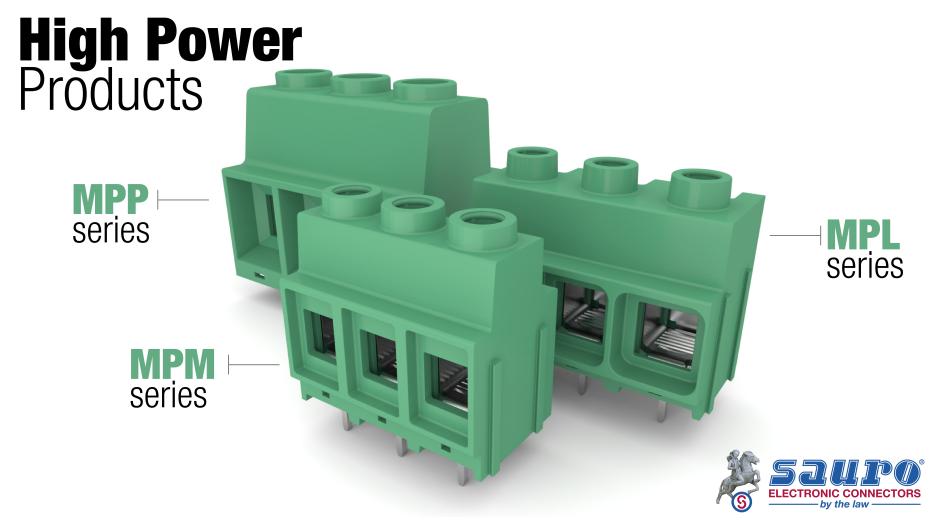

SAURO offers a high-quality range of high-power terminal blocks, available in different pitches, from 10,16mm to 15mm.

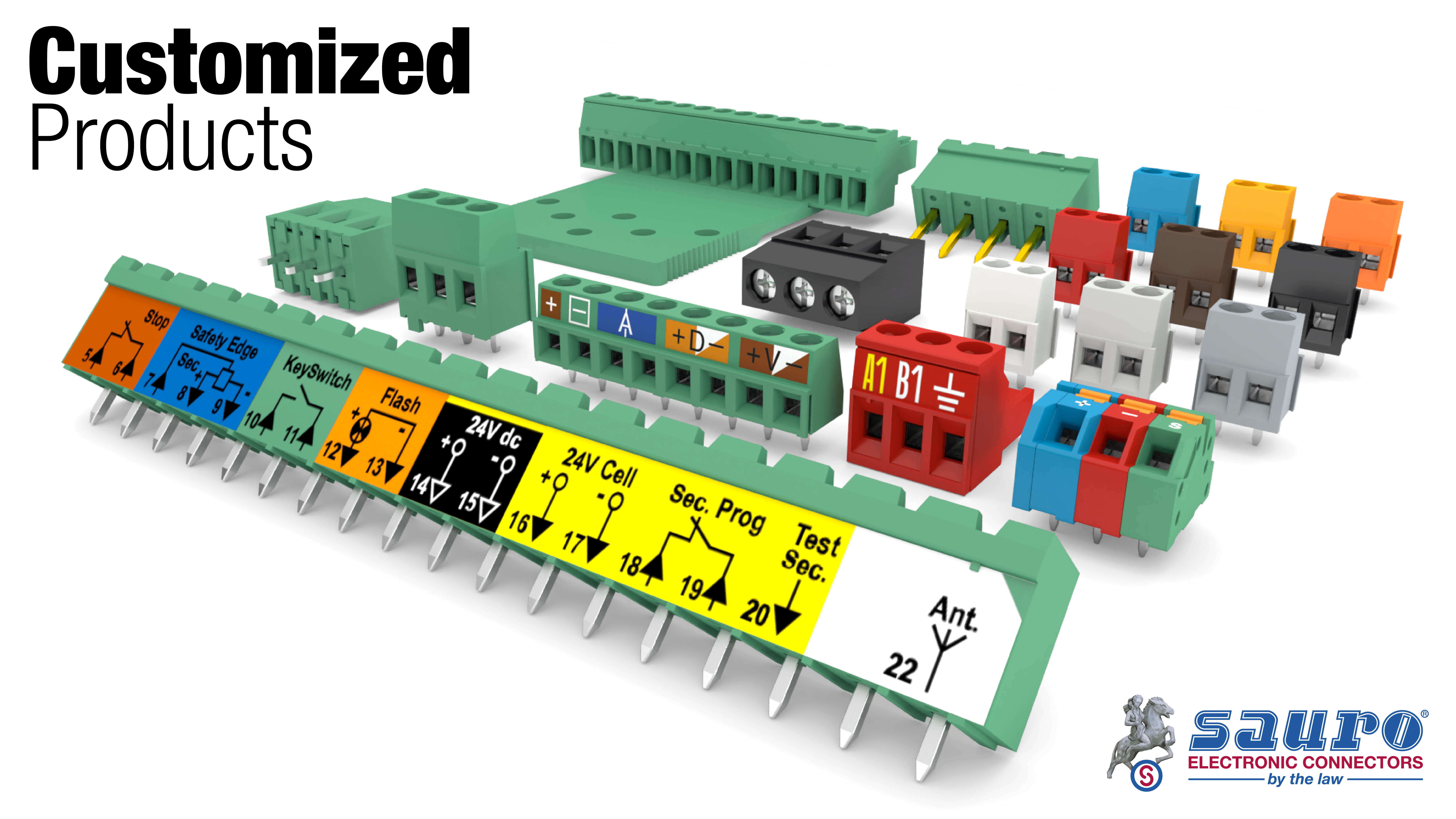

The specific series are: MPS, MPM, MPL and MPP. They are all screw-type products with rising clamp technology reaching very high performance. MPS and MPM reaches up to 76A, MPL 101A and MPP 135A with tension that can be of 1000V. A plus of MPS and MPP products is that are made in high temperature plastic material in order to be soldered inside the reflow oven together with all the other SMD products which are present on the PCB. All products can be customizable with different colors, pad printing and personalization on plastic housing and metallic components, according to SAURO philosophy to satisfy customer’s requirement. High-power products are designed for the use in POWER ELECTRONICS applications, particularly in: solar inverters, frequency converters, servo drives, power supplies, UPS - Uninterruptible Power Supply, e-mobility- electric car charging station, etc.