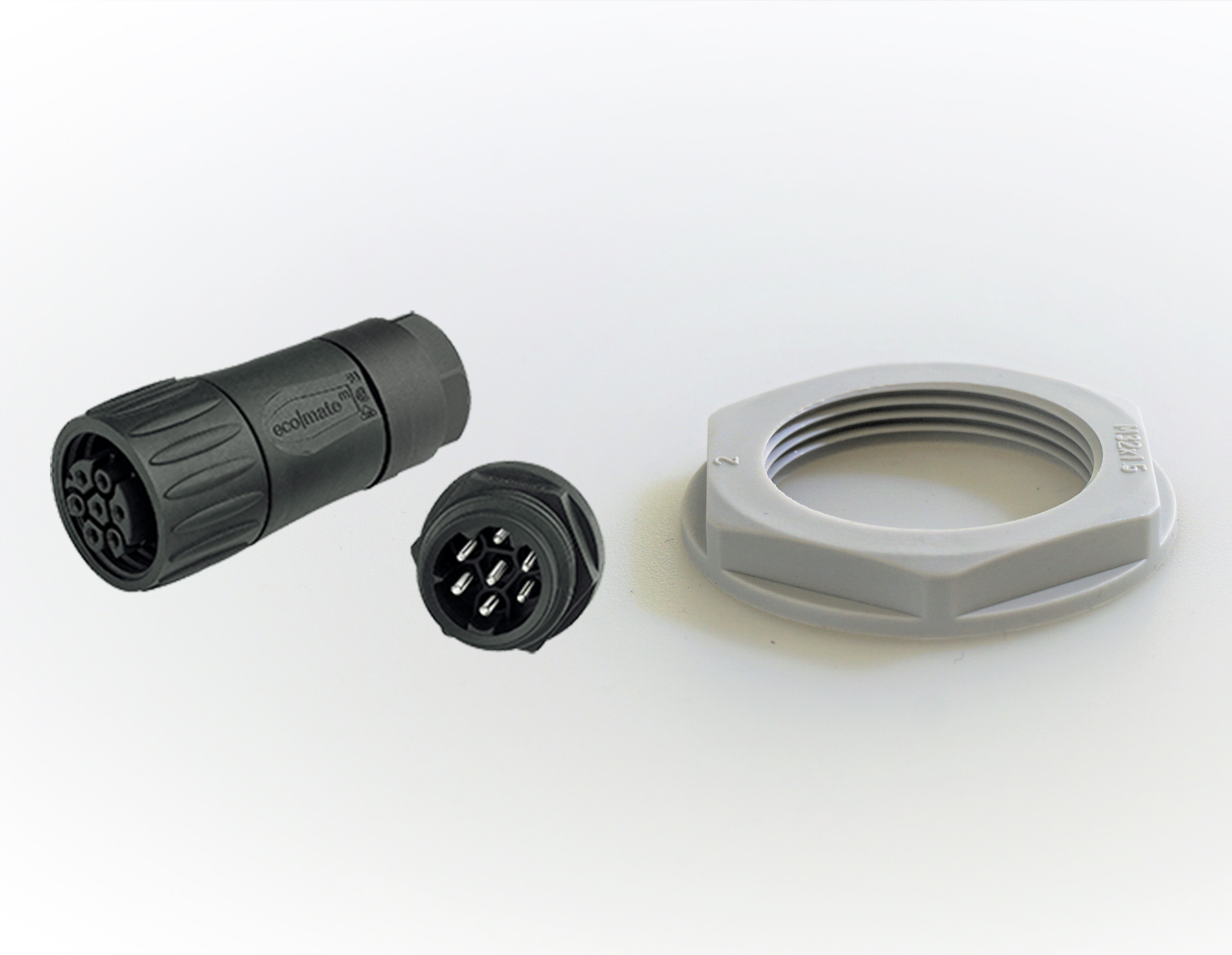

Customized Solutions and Cable Assemblies

Customized Solutions and Cable Assemblies

Description

Customized Solutions - Tailor-made solutions

We are the contact for product developers, engineers and purchasers who need application-specific solutionsfor special requirements and applications in the areas of cable entries, pressure equalisation, conduit systems and connectors. We offer you our services in a 5-step concept:

I. Consultancy and analysis before the contract is awarded

We advise you at an initial customer meeting and clarify the approach together with you on site. We then analyse the market in order to find the right system partner for you before the contract is awarded and to match the development and production costs to your budget. We can call on an existing pool of partner companies in this respect who are considered experts in their respective fields.

II. Contract conclusion and administration

Our team regulates the entire development process. Important framework conditions, such as tool type, ownership rights, maintenance intervals and production quantities are clarified and defined in the contract. We coordinate and document the entire project and can also obtain patents and approvals where necessary. The tools supplied for your product can also be transferred to your ownership if this suits your investment strategy.

III. Developing innovative products

In the next step, we develop your individual product with our team, focusing entirely on your specific requirements and visions. We use 2D and 3D drawings for you to visualise how the end product will look and operate. And we optimise the product with you until it fits your requirements.

IV. Handling the communication process

You don't have to worry about a thing. As a full-service provider we handle all communication with our partner companies. During the project we clarify with you whether we can use existing basic tools or if completely new tools are required. The costs of developing your product can be significantly reduced if basic tools already exist. We also work with you to determine which tool size is best for your product, what the annual production quantity should be (2-fold, 4-fold, etc.) and what costs this will incur.

V. Monitoring tool production

After the product's construction phase, we support and monitor the entire production process: from manufacture of the tool to start of production. We define the material with you, perform checks, document them and handle the sampling.