It pays off to be prepared – find out about all exhibiting companies and the entire product range that will be presented at the SPS this year. This will help you to get in touch with the right business partners.

Here you can find the exhibitors at the SPS 2025. This online search gives you an overview of the participating companies and will be updated regularly.

Use the various filter functions to search for specific product groups, halls, contact information and much more. The filters can also be combined with each other in any way, so that you can adapt the search to your individual criteria.

Exhibitor search SPS 2025

MicroControl GmbH & Co. KG

Address

MicroControl GmbH & Co. KG

Junkersring 23

53844 Troisdorf

Germany

Telephone+49 2241 256590

Fax+49 2241 2565911

Discover more from us

Follow us on

About us

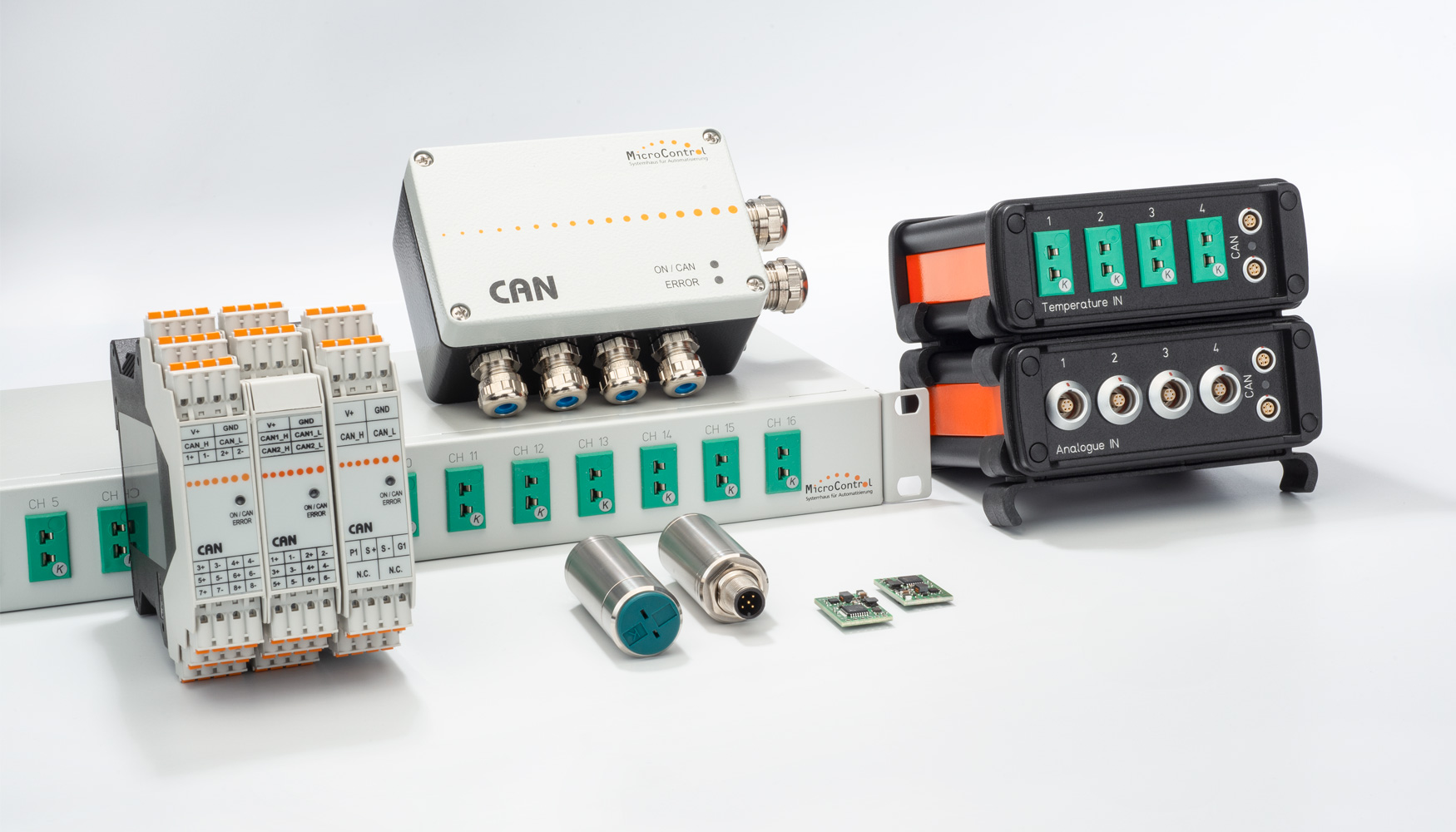

For more than 26 years, MicroControl has specialized in providing CAN bus applications for demanding industries as e.g. mechanical, automotive industry, renewable energy and medical technology. We provide excellent solutions to transmit analogue measurement signals such as temperatures or pressures to a CAN- or Ethernet-fieldbus interface during the process. Design, engineering and manufacturing of hardware and software components are „Made in Germany“ and organized by SAP ERP.

MicroControl's portfolio comprises I/O modules for digitizing analogue data obtained from pressure or temperature measurements for CAN bus as well as Linux based control systems which are compact and highly efficient. CANopen, CANopen FD and J1939 protocol stacks which facilitate fast software development complete our range of expertise.

MicroControl offers Training and Advisory Service for your projects. We are your development partner if you need to adapt your applications to the requirements of Industry 4.0 and company-wide networking. We plan and produce customized hardware and software solutions in a wide range of areas.

https://www.microcontrol.net/en/

Our product groups

Keywords

- IO Module, AD Wandler, EA Module, Druck, Temperatur, CAN-Bus, CANopen, FD, J1939, IO Modules, strain gauge, temperature

- Steuerungen, Control Systems, Control Units

- Entwicklung Hard- und Software, Developlemt hard- and software

- Webinare, Training, Schulung, Seminar, Workshop

- Protokollstacks, Protocol Stacks, CANopen, CANopen FD, J1939, Master, Slave, Bootloader, CANpie FD, Safety

Our Products

Protocol Stacks CANopen, CANopen FD, Safety, J1939 and CANpie FD Driver

Developers and engineers find protocol stacks helpful when defining interfaces. And field tested software of MicroControl provides even more advantages: This is why MicroControl‘s protocol stacks are the perfect choice:

They are most reliable: As our customer you will make use of MicroControl’s leading-edge protocol stack. MicroControl‘s presence and expertise in the BUS market guarantee central availability of protocol stacks for all current BUS systems.

They are faster: Our customizable software components are based on standard elements and sustainably improve transparency and effectivity. Precious time will be saved which will speed up your development and production processes.

They are more economical: MicroControl‘s protocol stacks set free valuable resources. They safe time for information and training, reduce sources of errors and facilitate functional control and performance.

CAN protocol stacks of MicroControl are now equipped with CANpie FD (CAN Programming Interface Environment, Flexible Data Rate). This standardized driver interface facilitates integration of various controllers.

Migration from CANopen Classic to CANopen FD is now possible at any time and only up to your entrepreneurial decision.

Long-term efficiency of this new generation of protocol stacks is a standard feature and Industry 4.0 requirements are met at the same time.

By the way: users of MicroControl's protocol stacks will benefit from our „fair partnership“: cost-saving company license (in contrast to widely-used runtime licenses) and 12 months free of charge support. A subsequent, optional maintenance agreement will contain automatic updates.

http://www.microcontrol.net/en/portfolio/protocol-stacks/

Advisory Service for your projects as well as individual hard- and software development through to series production

Conceptional design, development and series production of individual solutions are intrinsically tied to each other.

Conceptional design in close liaison with the customer and monitoring of self-developed solutions from prototyping to development and start of series production will provide maximum security, maximum performance, maximum benefit - and a desirable "more" compared with standard industrial solutions.

If companies want to decide on a future-proof bus technology, comprehensive advice will be needed in the early stages of the development process. We mostly start with a MicroControl workshop or webinar which will then be followed by support and advice in the research and development stage.

If the decision has been made for CANopen classic or FD, the MicroControl experts will work in close liaison with the customer to realise hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually. With more than 25 years of experience in project management in a variety of industries, we will be your reliable partner for future solutions.

Our technological backgroung and expertise are based on 25 years of experience in industrial process automation. Our presence in technological associations and cooperation with universities have been an important aspects of a constructive dialogue. MicroControl benefits from a mutual exchange of information and ideas in guest lectures, seminars as well as internships and diploma theses.

Development and project management are based on current software standards. such as the open programming tool "Eclipse" and "Altium Designer" for PCB development. Efficient project management is facilitated by "Easy Redmine".

MicroControl provides quality. This statement is confirmed by regular QS audits of our customers. Only certified companies can become part of our production network. and as our long-term partners they are focussed on the timely provision of high-quality products.

https://www.microcontrol.net/en/portfolio/advisory-service/

https://www.microcontrol.net/en/portfolio/development/

Training - Webinars standard and customer specific as well as Inhouse Workshops

Benefit from our know-how about CAN, CAN FD, CANopen, and J1939. We offer Training on these specific subjects. You will discover the opportunities of bus technologies.

Our webinars are held in two compact parts of four hours each and will save time and travelling costs. The webinars are held in German or English as desired.

Our presence workshops are held in small groups at fixed intervals and take place in our Troisdorf training center – conveniently situated near Cologne. (Due to the dynamic development of the Covid pandemic, we will not offer any presence workshops on CAN basics, CANopen and J1939 in our Troisdorf training centre until further notice. We will inform you as soon as there are any news.)

We also offer individual in-house workshops or webinars for your company tailored to your specific requirement and level of knowledge. We are a competent industrial education partner who will train your team on essential knowledge and current developments in global BUS technology.

MicroControl has been offering this kind of trainings for several years. Customers and professionals have been using MicroControl's range of in-house and intensive workshops on BUS technology for more than 25 years. MicroControl's presence in various BUS markets guarantees up-to-date hands-on workshops.

https://www.microcontrol.net/en/portfolio/training/

Control Units

With its controller unit µMIC.200 MicroControl provides an innovative control system which is capable of more than a traditional industrial control unit can offer. Based on MicroControl's wealth of experience from hundreds of individual customer projects with their specific needs and requirements the µMIC solution offers everything the user may need in practice. Also, the requirements of Industry 4.0 are met as the control unit can easily be integrated into existing IT structures.

Compared with conventional mini control units MicroControl's µMIC.200 has a wider working temperature and supply voltage range and provides higher flexibility due to customizable electronics. With its rugged metal casing it is ideally suited to work reliably in harsh environments. And all that at very favourable conditions.

μMIC control units can be programmed with Node-RED open source software or in C/C++.

Node-RED offers:

- an intuitive graphic user interface

- quick results for prompt application

- no additional local software installation

- simply use μMIC and start working

- easy and quick connection to IoT Cloud services / Industry 4.0

More demanding specifications can be realized with the C/C++ programming option.

Getting started is easy using the freely available Eclipse IDE. All the tools necessary such as editor, compilers, debuggers, ssh shell are integrated in one single programme.

The real-time Linux operating system facilitates flexible development of applications software. The µMIC.200 may be connected to any PC or Notebook through its integrated Ethernet interface. Due to its secure Linux-Kernel and VPN function (virtual private network) programmers may access the µMIC.200 from everywhere without further investments.

Our freely programmable Linux based control unit µMIC.200 is equipped with an ARM Controller which is clocked at a maximum of 1 GHz. The module provides 512 MByte RAM as well as 4 GByte Flash memory which may be extended via the microSD slot. The maximum power consumption of the modules is 4 Watts.

Equipped with eight configurable digital in-/outputs, a relay, four freely controllable LEDs and a real-time clock the µMIC.200 may be used in a multitude of different applications. Digital signals, CAN bus and RS-232 are connected to the control unit via plug-in COMBICON® connectors. All I/O modules which are equipped with CANopen interface may be connected via the integrated CANopen FD Master Library.

http://www.microcontrol.net/en/portfolio/control-units/

I/O Modules CANopen / CANopen FD and NEW SENSOR CONNECTION

MicroControl's sophisticated I/O modules are available as highly economical serial products or may be customized to your specific requirements as development, engineering, configuration and manufacturing are Made in Germany.

The new modules with CANopen FD are faster and more powerful; up to 10 times faster and significantly higher data throughput; your existing CAN structure can be maintained; no additional investment in infrastructure; easy integration in existing networks; no modification of cables or plugs. Measurement technology and automation at highest level: Industry 4.0 becomes reality.

And this is why MicroControl components are more efficient than conventional industrial electronics:

Enhanced temperature range, higher resolution, broadened power supply range and higher IP rating.

10 Years guaranteed availability

Future standards: The constistens hardware platform: significantly higher processing power; up to 50 % faster than current industrial standard; considerably reduced power consumption etc.

The consistent software platform: individual customer specifications and adaptions can quickly be realized on all MicroControl modules; high processing power due to FPU/DSP; dynamic PDO mapping; buffered real time clock; all modules equipped with standard CANopen Bootloader etc.

Präsentation auf der SPS: NEUE SENSORANBINDUNG

Profitieren Sie von den Highlights unserer neuen CAN Sensoranbindung:

CAN-Interface: The integrated high-speed interface supports the protocols CAN classic, CANopen, CANopen FD and J1939. Information about other protocols on request.

Measurement signals: Acquisition of strain gauges, voltages, currents as well as temperature signals up to a sampling rate of 1 kHz.

Design: The miniaturized electronics is available as 1- or 2-channel module to be integrated in a sensor. With its IP67-ranked stainless steel casing the module is ideally suitable for applications directly in a machine.

http://www.microcontrol.net/en/portfolio/io-module/