It pays off to be prepared – find out about all exhibiting companies and the entire product range that will be presented at the SPS this year. This will help you to get in touch with the right business partners.

Here you can find the exhibitors at the SPS 2025. This online search gives you an overview of the participating companies and will be updated regularly.

Use the various filter functions to search for specific product groups, halls, contact information and much more. The filters can also be combined with each other in any way, so that you can adapt the search to your individual criteria.

Exhibitor search SPS 2025

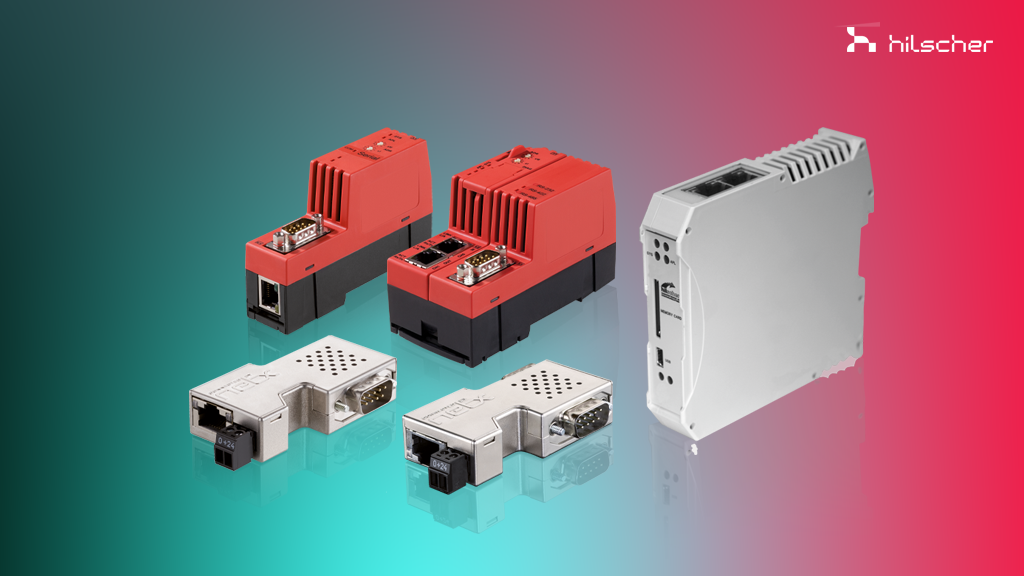

IO-Link Wireless Master for Industrial Ethernet

Description

From retrofitting existing systems to the seamless integration of sensors into real-time communication networks, IO-Link is the standard for industry 4.0.

The wireless netFIELD IO-Link wireless technology allows you to wirelessly integrate complex sensors or actuators into Real-Time Ethernet networks. Reducing cables accelerates device integration time and reduces the risk of physical damage such as cable breaks. Devices also have increased freedom of movement, which is especially relevant for robotic arms or autonomous transport vehicles. At the same time you benefit from the entire Hilscher ecosystem with regular firmware updates, pre-certified protocol stacks and our many years of experience in industrial communication.

- REDUCTION OF INSTALLATION EFFORTS

The wireless point-to-point communication technology enables the cyclic exchange of digital input and output process data between the Master and its associated devices. - INCREASE OF COMMUNICATION CHANNELS

Traditional hardwired IO-Link masters only offer eight ports in most cases, half the amount of Hilschers Wireless Master. - PROFESSIONAL SOFTWARE SUPPORT

Hilscher provides comprehensive software tooling such as an IO-Link configuration tool. - ACCESSIBILITY OF SPACE LIMITED AREAS

Sensors and actuators only require a 24 V power supply to transfer data via Hilschers IO-Link Wireless Bridge to the master and vice versa. - HIGHER RANGE OF MOTION

Utilizing wireless technology for data transmission minimizes movement restrictions for industrial robots, cobots and other machines. - ALLEVIATE DOWNTIMES

Wireless data connections will not break due to physical stress as a result of moving robot arms for example.

Address

Hilscher Gesellschaft für Systemautomation mbH

Rheinstr. 15

65795 Hattersheim

Germany

Telephone+49 6190 99070

Fax+49 6190 990750