Delivering TSN’s benefits to manufacturing

Delivering TSN’s benefits to manufacturing

Description

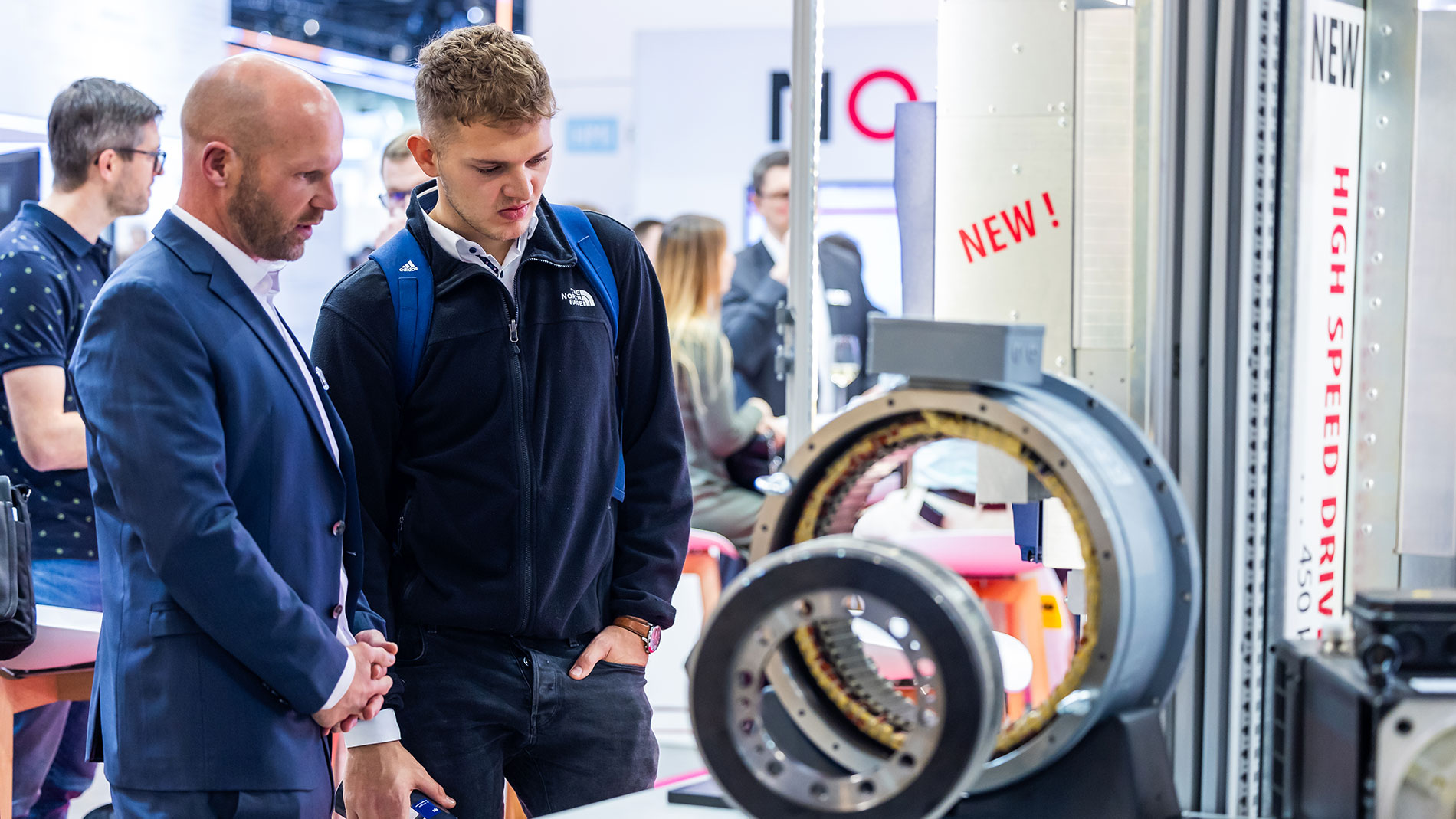

The transformative potential of Industry 4.0-oriented digital technologies in manufacturing is widely

recognised. However, the “explosion” of data these have created is a double-edged sword. On the

one hand, the data has the potential to be transformed into valuable information that can deliver

actionable insights for optimising processes. But on the other, if not managed well, this data threatens to become a tidal wave that will overwhelm companies and create more problems than it solves.

Key to the management of this data is a converged, high bandwidth network infrastructure in order

to succeed with value-adding digital transformation strategies. In simple terms, convergence is

the concept of allowing everything to share the same network architecture to communicate,

hence avoiding the complexity and cost of multiple networks. The ideal system should be the

foundation of high-speed, real-time deterministic communications between disparate devices

and systems, allowing data to be shared across the entire enterprise, regardless of its source or

destination. The ultimate aim is to provide the process transparency required for fully optimised

operations by allowing the data to flow from its source to where it can be processed to obtain

actionable insights and then fed back into the process. This does not just apply to supervisory

systems. Having real-time control and coordination of multiple different shop floor or operational

technology (OT) systems is also critical.

This white paper explores the network technology that can address these challenges, Time-

Sensitive Networking (TSN). TSN can deliver four specific benefits to a range of industries,

specifically:

1. Reduce costs, shorten project timelines and increase uptime by simplifying network

architectures and hence machine designs. By employing convergence, systems no longer

need multiple network types to handle all process traffic.

2. Deliver greater process transparency and optimised operations. As a consequence of

converged network architectures, having data flow to where it is needed is simplified. As we

discussed above, this is the key to managing processes in the best way.

3. Greater productivity, as optimised processes will run in the most productive way.

4. Better integration of OT and information technology (IT) systems, as a converged stream of

data can be shared from the factory floor to supervisory systems more easily. Hence getting

the data to where it can be analysed is simplified and this further contributes to process

optimisation.