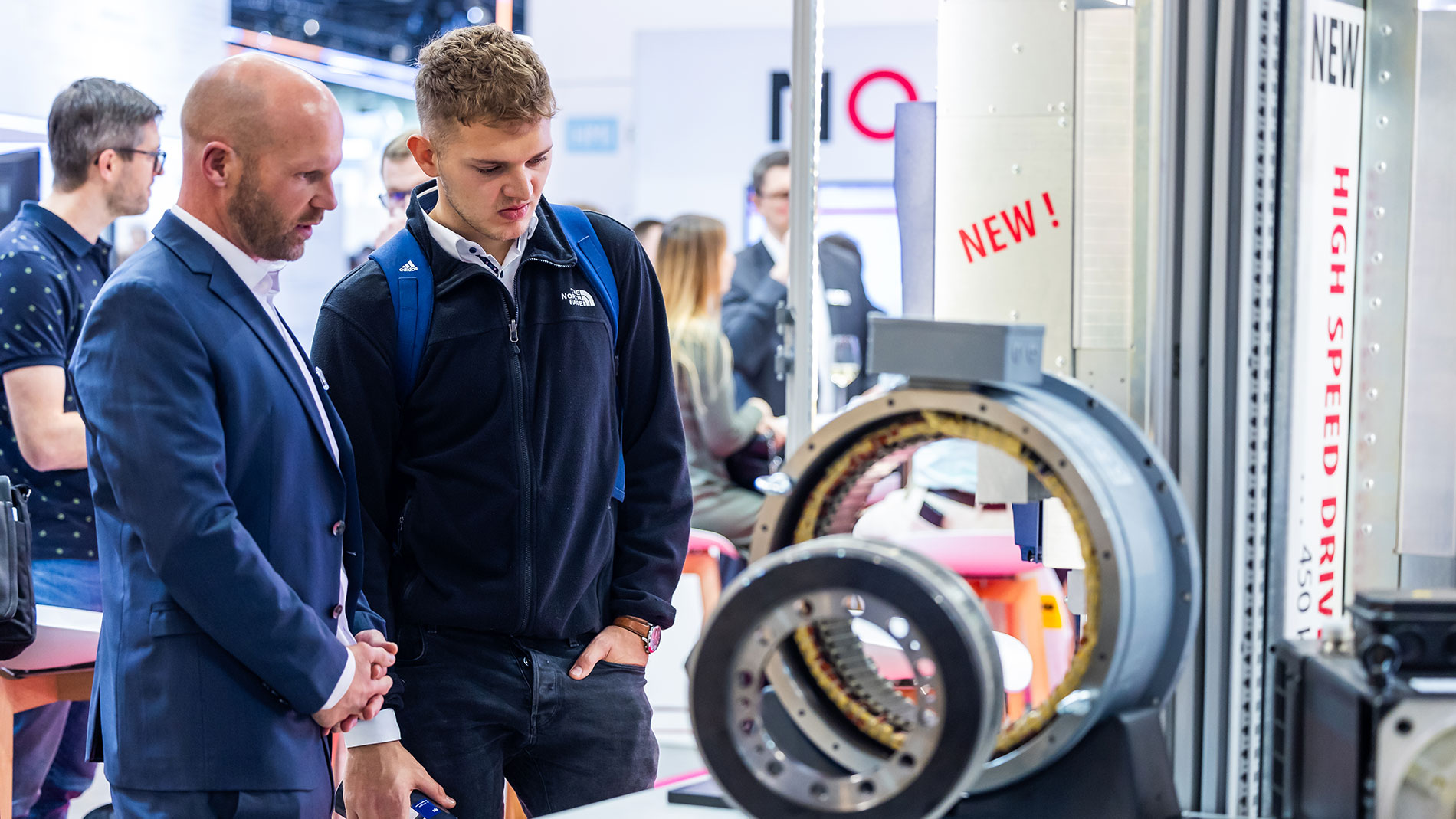

Inspire the next Gen!

At the SPS 2025, you will meet the talents of tomorrow. Whether through Guided Tours, the Makeathon, or strong on-site presence – win over the next generation for your company.