Smart Vibration Monitoring software

Smart Vibration Monitoring software

Description

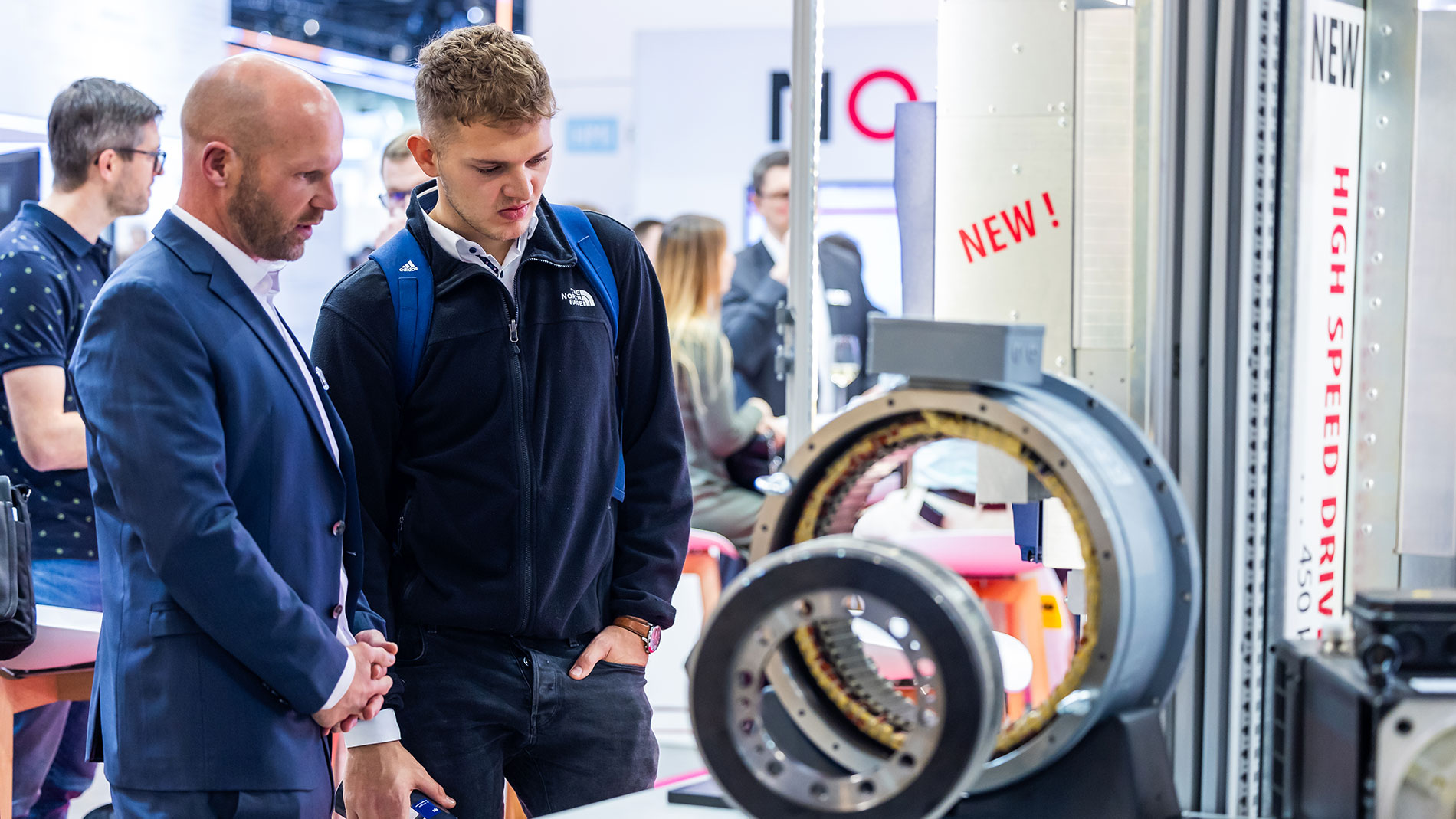

Increasing productivity and enabling new business models through smart drive solutions

Condition monitoring solutions allow operators to keep track of the condition of many machines on a regular basis. For example, wear on motors can be identified early, preventing potential machine downtimes. However, if this function is performed via sensor, it can quickly get very complicated and costly, depending on the type of machine and the number of motors used, such as in a textile machine.

The new Smart Vibration Monitoring software solution allows machine manufacturers to offer their clients condition monitoring without external sensors. The software is directly integrated in the servo-controller using softdrivePLC, making it easy to retrofit and update. Machine manufacturers thus have new options, such as offering runtime models for additional machine functions.

The new function uses previously recorded and analyzed process parameters as reference values for monitoring the mechanics, such as the electric motor, fan, or hydraulic pump. The software detects vibrations, such as those created by imbalance or improper alignment, early on and sends an error signal. This allows planned maintenance to be carried out on the motor, preventing further damage to or failure of the machine.