Industrial Robots and the Challenge of Isolation

Industrial robots are everywhere. But too often, they operate in isolation. They cannot easily communicate with each other. They are difficult to reprogram. And they require manual coordination to adapt to change.

The Cost of Downtime on the Factory Floor

You feel this on the factory floor. Every time a process changes, or a customer demand shifts, you wait. You rely on outside support. You risk downtime, and it costs you.

The Problem Lies in the Software

The problem is not the robot. It is the software around it. Each brand comes with its own language, its own constraints, and its own learning curve. Updating one system can take hours. Coordinating across several takes weeks. The result is fragmented automation and limited flexibility, when your business demands speed.

Moving Toward Software-Driven Automation

You need a way to unify your systems, test changes before they hit the floor, and make decisions based on real production data. That means moving away from static, hardware-dependent processes to dynamic, software-driven methods and tools.

Introducing Wandelbots NOVA: A Unified Robotics Platform

This is where NOVA helps.

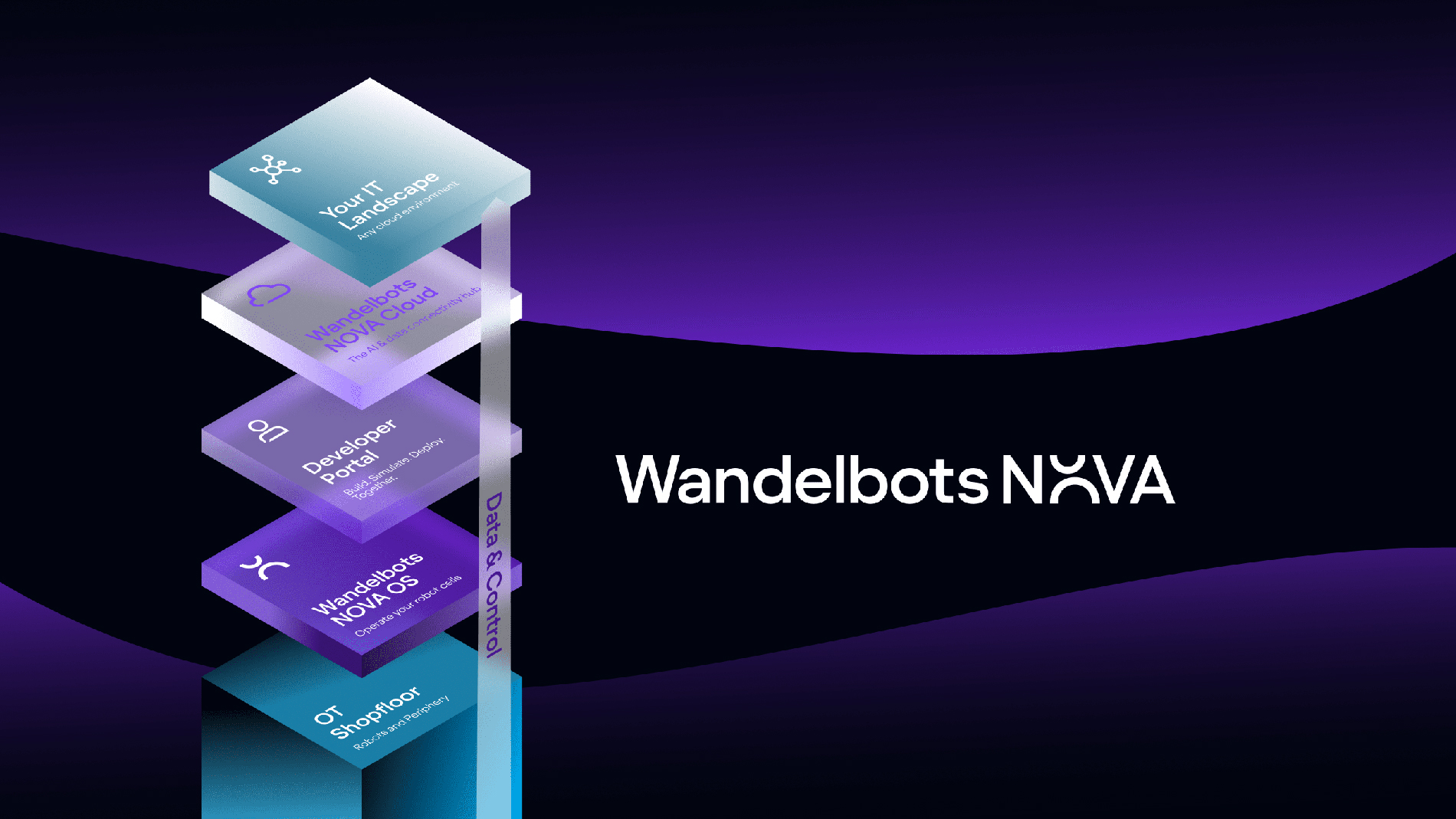

NOVA is a vendor-agnostic software platform that connects and controls robots across your production network. With NOVA Operating System, you gain a single interface for major robot brands including KUKA, FANUC, ABB, and Yaskawa. You can program in Python, TypeScript, or other modern high-level languages using native developer tools like Visual Studio Code, Jupyter Notebook, or your preferred environment. You can create, simulate, and deploy new paths directly from your workstation. You avoid long integration cycles. You reduce dependency on external service teams.

NOVA Cloud: Connected Robots and Real-Time Insights

With NOVA Cloud, you take this further. Your robots become intelligent nodes in a connected system. Real-time data streams directly into analytics tools such as Microsoft Power BI and Microsoft Fabric. You track production, detect inefficiencies, and plan changes with confidence. You shift from reactive maintenance to predictive insight. This is where simulation meets execution. Physical AI.

Partnerships Driving Robotics Innovation

Through strong partnerships with Microsoft and NVIDIA, NOVA connects to simulation environments like NVIDIA Omniverse. You model production, test workflows, and verify results in digital twin environments, then seamlessly deploy validated workflows to physical systems without reprogramming. NOVA closes the loop between simulation and execution, so you can validate use cases, confirm ROI, and move to production with confidence. One manufacturer used this setup to identify efficiency gains worth tens of millions. All from one week of virtual work.

Real Results in Industrial Manufacturing

This is not a concept. It is already happening. Today, manufacturers like Schaeffler are using NOVA to cut robot cycle times, predict quality issues, and scale automation across locations. This works without adding new machines or writing custom code. And because NOVA is software-based, you gain flexibility from day one.

Unlock the Full Potential of Your Robots

You do not need more robots. You need to unlock the potential of the ones you already have.

Connect them. Simulate workflows. Orchestrate intelligently. And transform how your production runs.

Efficiency Starts with Control

Because efficiency starts with control. And with the right platform, control is in your hands.

About Wandelbots

Wandelbots is a deep tech company based in Dresden, Germany, that is radically rethinking industrial automation, especially in logistics and production. With its disruptive, software-centric approach, Wandelbots is driving the transformation of industry. It empowers companies to transform industrial robots into software-defined, continuously optimizing systems with an end-to-end platform consisting of NOVA Cloud, NOVA Operating System, and Developer Portal. For more information, visit http://www.wandelbots.com or follow us on LinkedIn.

More information

For more information, visit www.wandelbots.com.