The exhibitors of the SPS 2026 are expected to be published in spring 2026. Until then, you can find the exhibitors and products of the SPS 2025 here.

Exhibitor search 2025

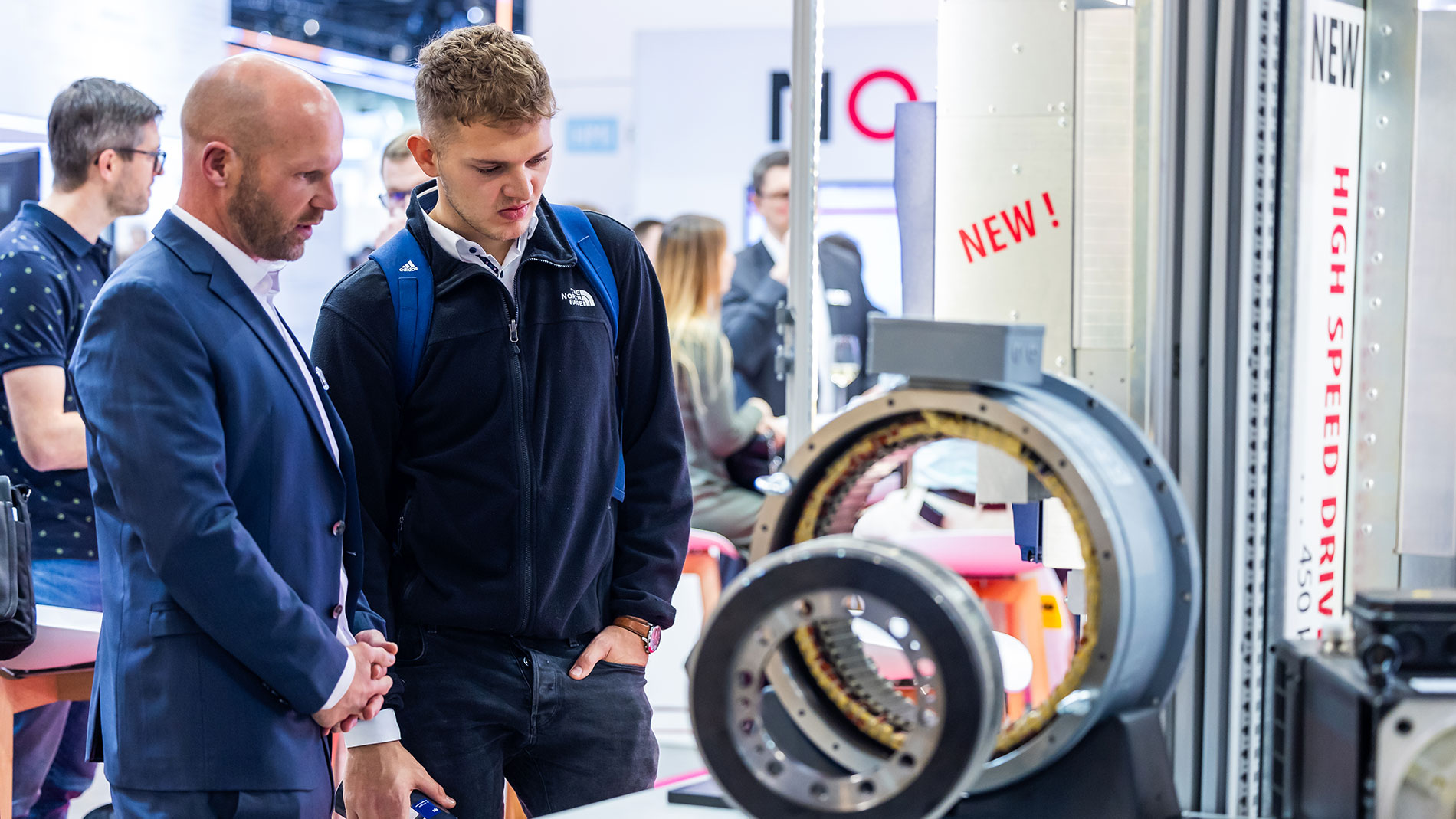

KEB Automation KG

KEB Automation KG

Südstr. 38

32683 Barntrup

Germany

Telephone+49 5263 4010