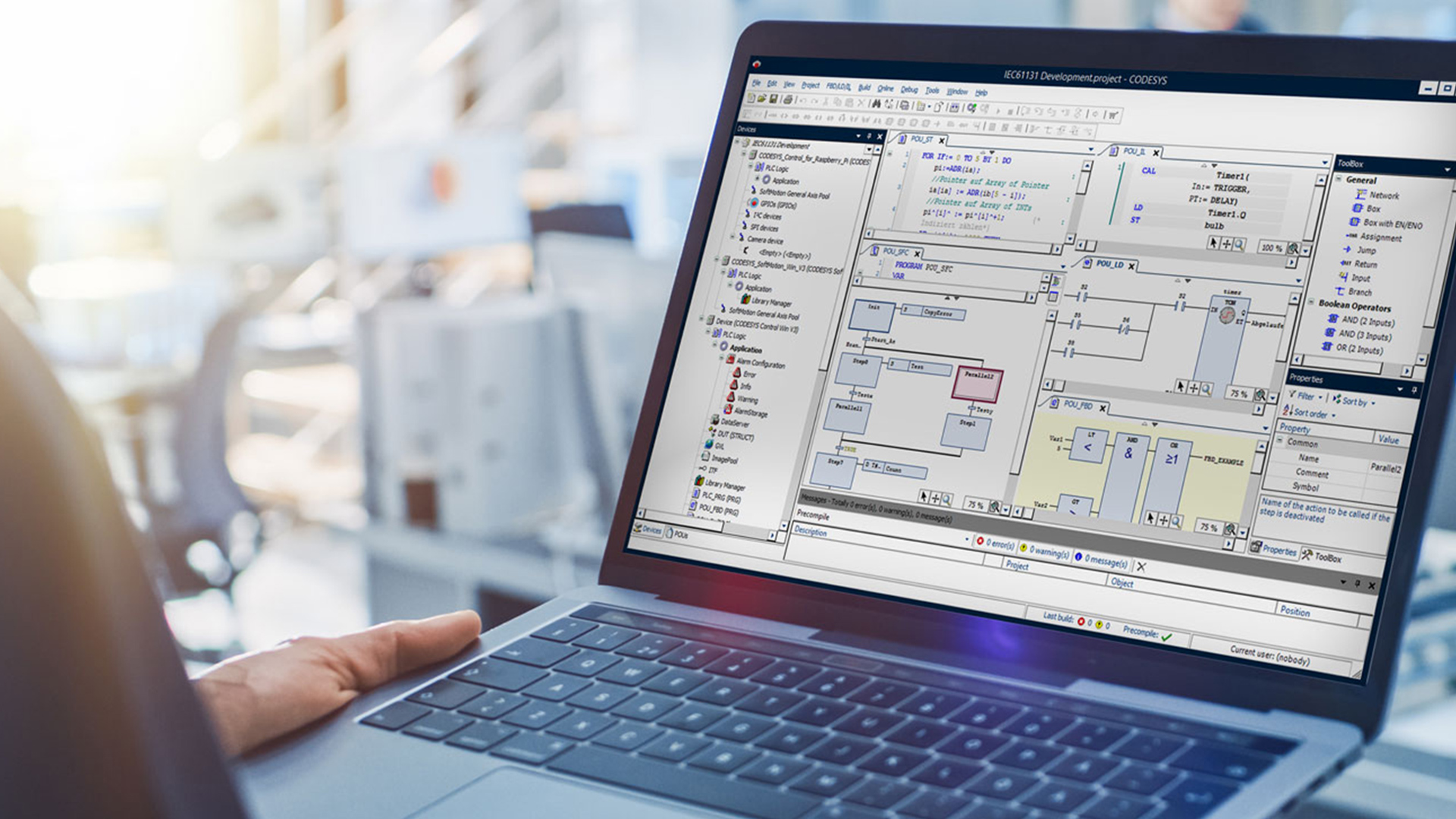

CODESYS Virtual Control SL / CODESYS Virtual Safe Control SL

Beschreibung

Virtual and secure industrial controls

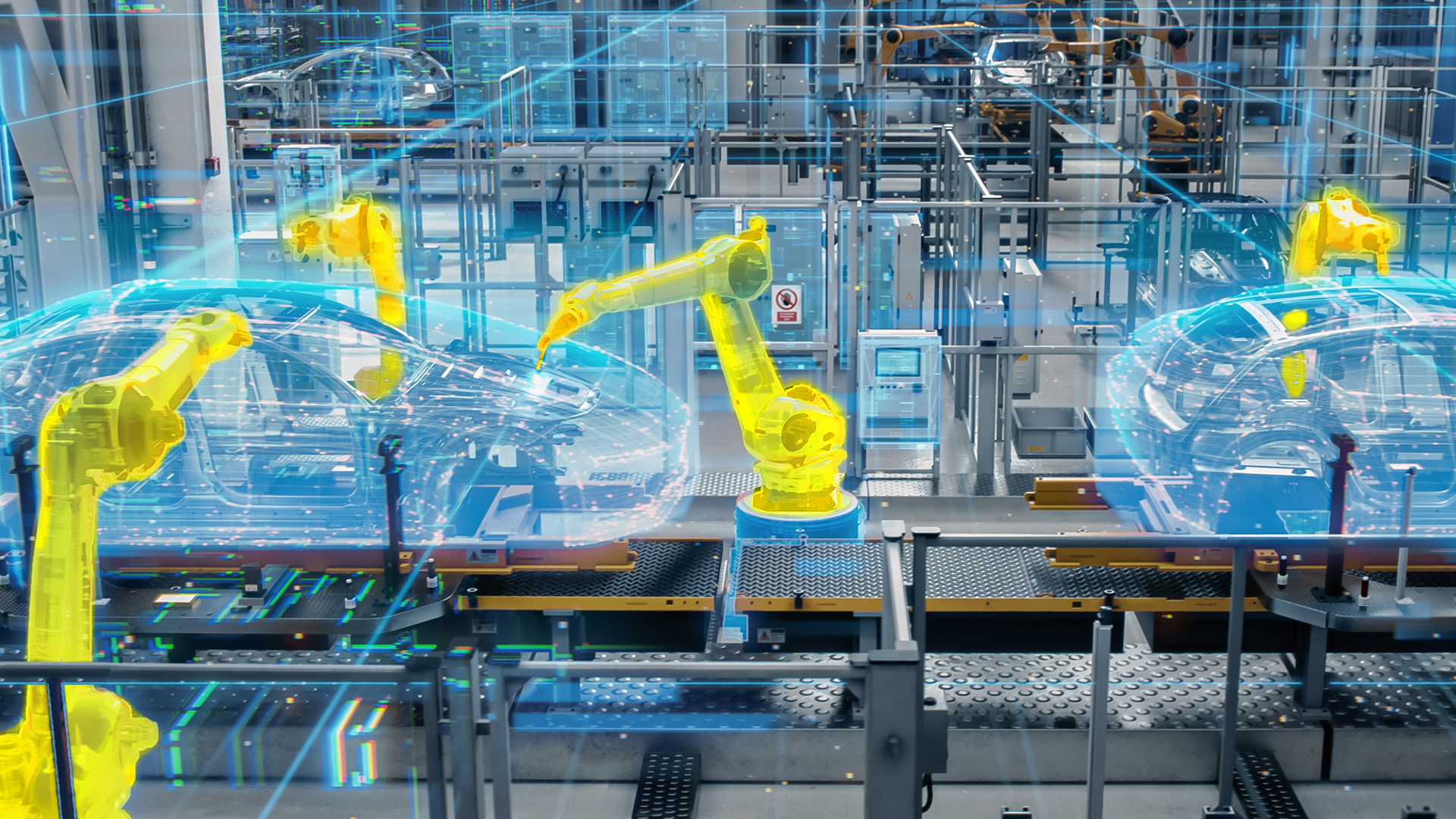

Although software is becoming increasingly important in control systems, its execution is still tied to physical hardware. Virtualization using container technology now makes it possible to abstract the hardware. This means that PLCs can be executed on different platforms such as industrial PCs, edge computing systems, or servers.

The necessary components of the PLC are “deployed” as an image in a container. This means that several PLC instances can be operated in parallel, allowing flexible and scalable utilization of memory and computing capacities. Physical or virtual network interfaces can be mapped to the PLC so that several fieldbus systems can be operated via a single port. The real-time capability of the controller is ensured by the operating system or real-time patch.

In safety-critical applications, e.g. in accordance with IEC 61508, compliance with safety requirements is crucial. A dual-channel control architecture is required for SIL3 at the latest. Virtual controllers enable software-based dual-channel capability without special hardware thanks to “Diversified Encoding”. The technology is based on “coded processing” and offers the possibility of detecting errors in the data and control flow of the PLC programs through redundant software channels. These channels execute the safety application one after the other on the same CPU core. In combination with other test mechanisms, this process achieves a level of safety comparable to that of dual-channel hardware - but without the need for special hardware.

As a control platform, CODESYS is device-independent per se. With CODESYS Virtual Control and CODESYS Virtual Safe Control, virtualization can be used directly in industrial automation. Your advantages:

- High cost and effort reduction for procurement, installation, and maintenance

- No need for special safety hardware

- Greater efficiency by freeing up control cabinet space and eliminating power supply units and cabling

- Optimized operating technology (OT) through central management of PLCs with modern IT methods

- Increased IT security through “Secure by Design”: Isolation of individual components in containers

- Simple generation of additional virtual controllers on existing resources instead of installing additional hardware

Adresse

CODESYS GmbH A member of the CODESYS Group

Memminger Str. 151

87439 Kempten

Germany

Telefon+49 831 540310

Fax+49 831 5403150