DELMIA Robotics

Beschreibung

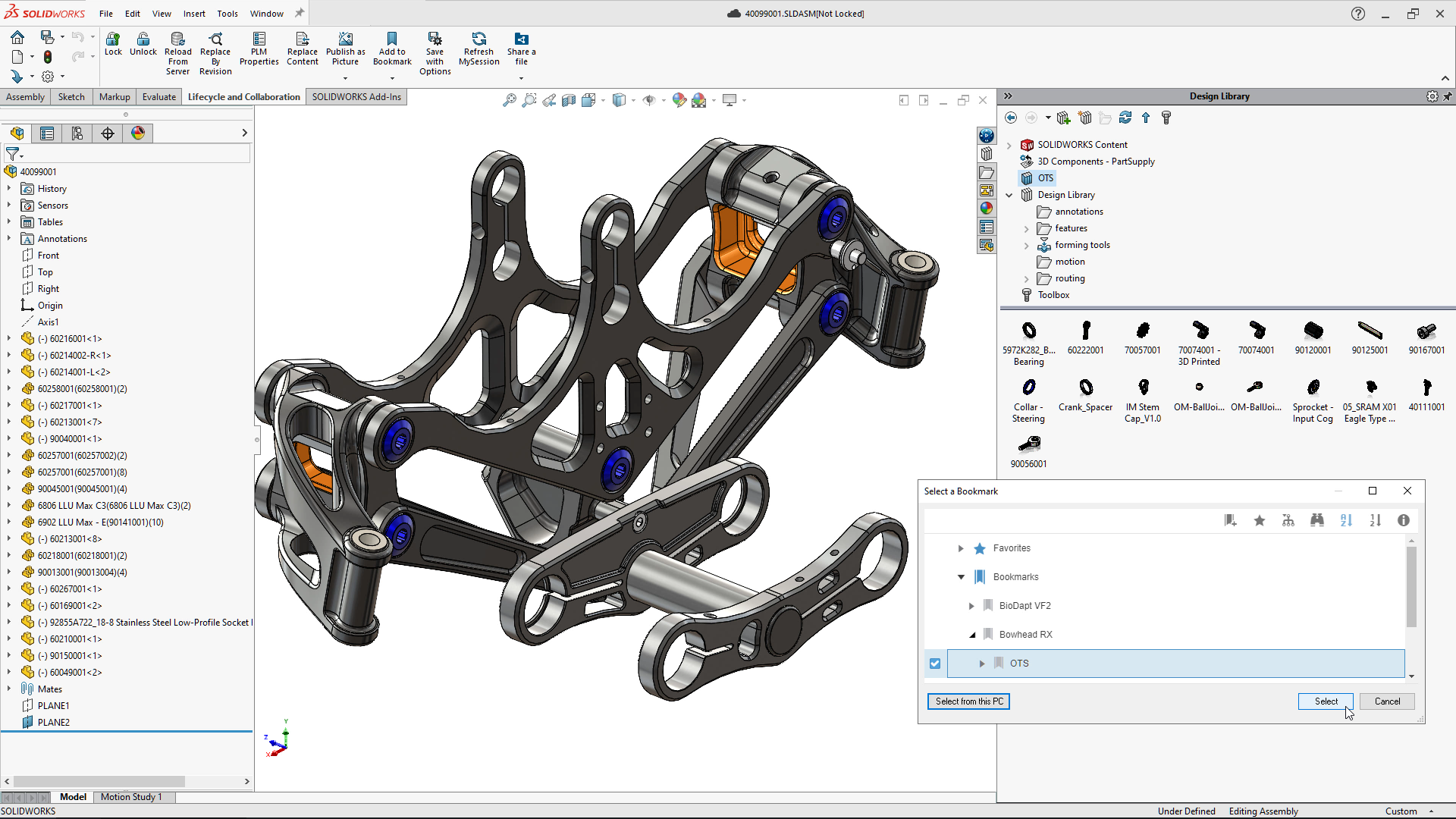

DELMIA Robotics enables the validation of production systems and robot programming in a 3D environment, even before physical production systems are created. This flexible solution supports the development of robotic cells, including tools and auxiliary equipment for programming and optimizing robots. Simultaneously, the entire manufacturing environment and product flow are simulated. Robotic simulation functions allow for efficient validation of production systems and robot programs without the use of physical resources.

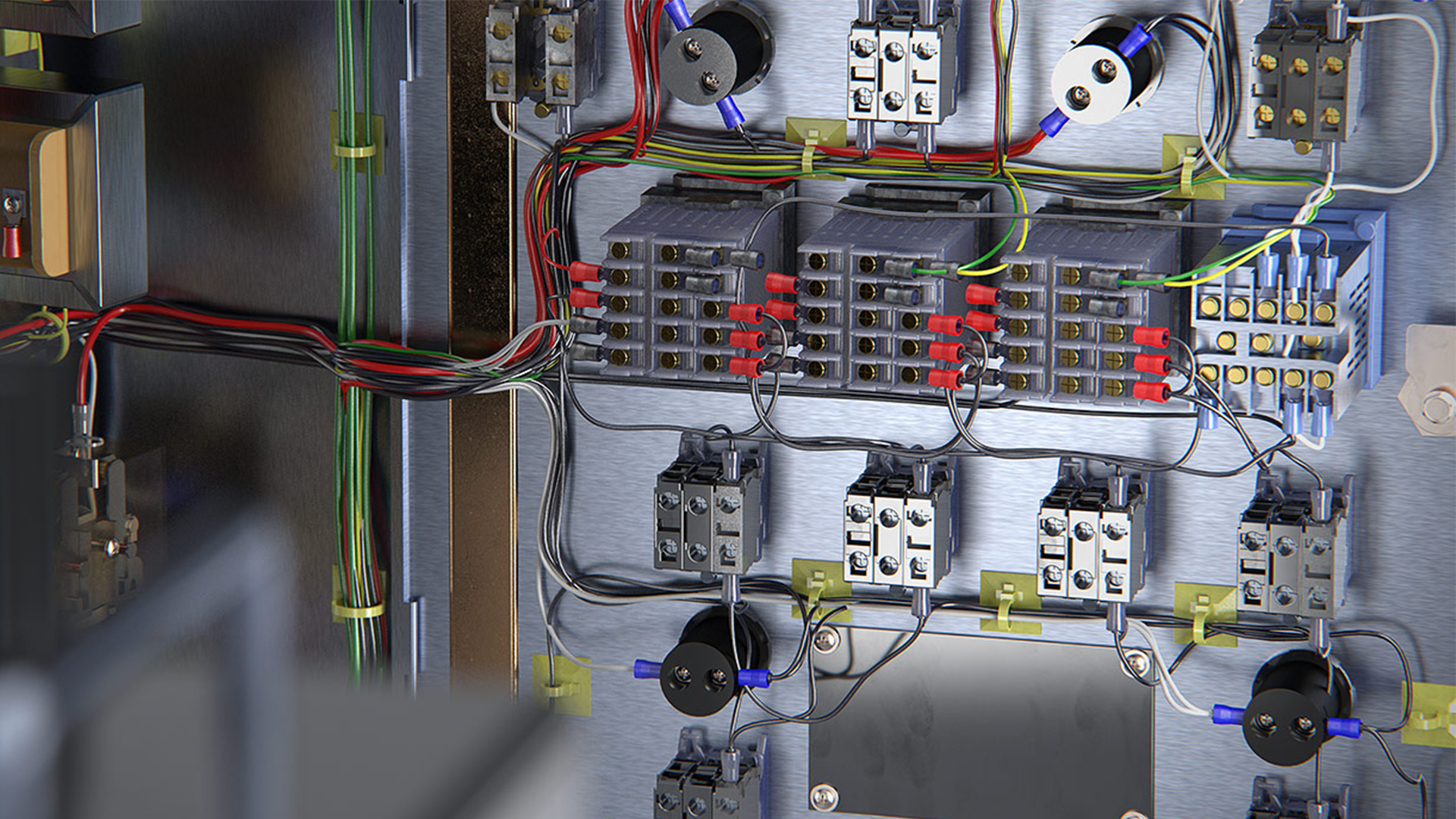

DELMIA is used across various industries to validate robotic processes such as drilling, riveting, welding, material handling, painting and sealing. The software offers comprehensive functions for simulating, optimizing and validating the entire robotic process. It facilitates collaboration within and outside the company through controlled data availability and improves the efficiency of robot programming.

The 3DEXPERIENCE Works role supports the management of the entire manufacturing process, including layout, simulation, validation, calibration, and offline programming on the 3DEXPERIENCE platform. DELMIA is an agnostic solution that enables programmers to program any industrial robot offline without needing to know its native robot language. The validated robot program can then be prepared for execution in production by translating it into the robot's language. Translators are available for all robots and can also be customized. For more precise simulation of robot movements and more accurate cycle time estimation, it is possible to connect the original robot control software (RCS) with simulations and OLP software (RRS standard).

Key Features:

- Offline Programming: Robot programs can be created and optimized without interrupting ongoing production. This saves time and costs by using digital twins for virtual validation.

- Virtual Commissioning: Before uploading the control program to the actual plant, the robot system can be tested virtually to identify and resolve potential issues early on.

- Collision Detection: Collision detection and cycle time analysis ensure a safe and efficient production environment.

- Seamless Integration: The solution allows for the customization and integration of company data into a central information source. This enables production to continue while new programs are developed and tested.

Adresse

Dassault Systemes Deutschland GmbH

Meitnerstr. 8

70563 Stuttgart

Germany

Telefon+49 711 273000

Fax+49 711 23700599

Entdecken Sie mehr von uns