Beschreibung

CONNECT: Die digitale Brücke für Ihre Produktion – herstellerunabhängige Konnektivität, maximale Datentransparenz

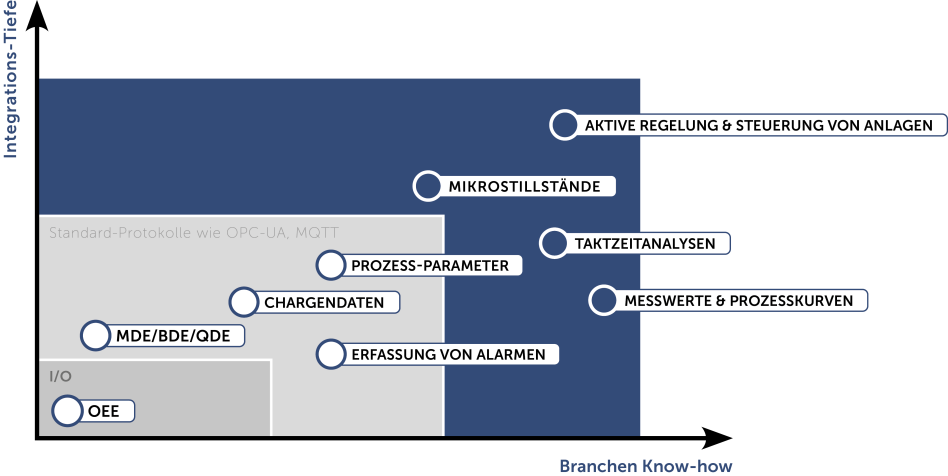

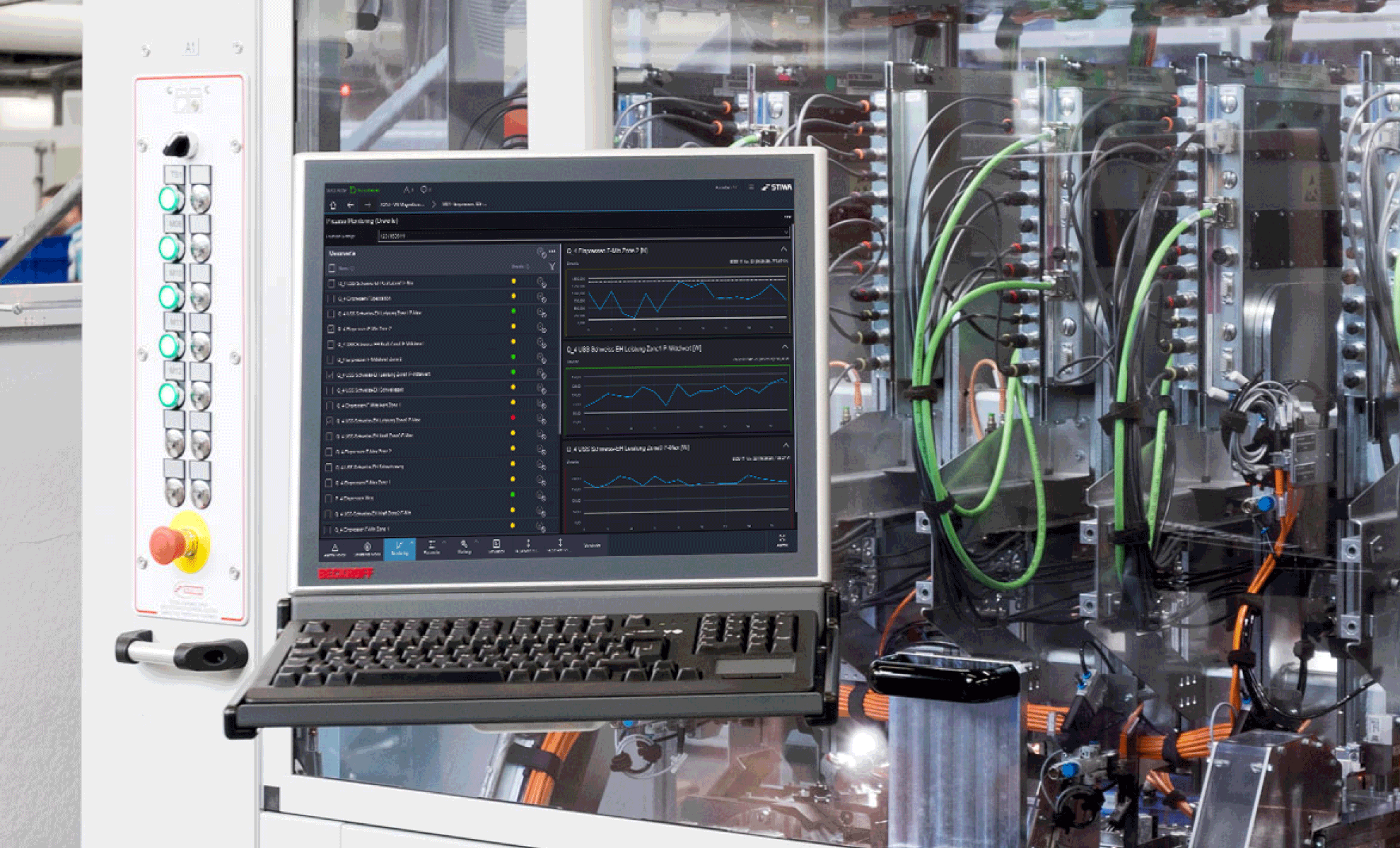

CONNECT bildet das Rückgrat des STIWA-Ökosystems. Es ermöglicht die herstellerunabhängige Anbindung von Maschinen, von einzelnen Standalone-Geräten bis hin zu hochkomplexen Linien. Durch die Standardisierung von Daten aus unterschiedlichen Quellen (OT/IT) wie Maschinen, Sensoren, ERP und MES bietet CONNECT Echtzeit-Einblicke in Ihre Produktionsprozesse. Diese umfassende Datenerfassung (MDA/PDA/QDA) bildet die Grundlage für STIWA CONTROL und OPTIMIZE.

Standardisierte Schnittstellen (z. B. OPC UA, ProfiNet) und die bewährte MaCo-Schnittstelle gewährleisten eine reibungslose und zuverlässige Datenkommunikation. CONNECT ermöglicht eine nahtlose Machine-to-Machine-Kommunikation (M2M) für globale Konnektivität und effizienten Datenaustausch. Ob Brownfield oder Greenfield – flexible Konnektoren integrieren ältere Systeme und modernste IoT-Technologien nahtlos und ermöglichen so eine schrittweise Digitalisierung ohne hohe Investitionen.

Wir greifen die Daten dort ab, wo sie entstehen. Vernetzen, was zählt

OT, IT und M2M Connectoren

- Bidirektionale Maschinenanbindung und M2M Kommunikation

- Standardisierte Kopplung zu gängigen MES und ERP Systemen

Tiefes Branchen-Know-how für die Erfassung von Mess- und Prozesskurven sowie Mikrostillständen

- Maschinen- und Betriebsdatenerfassung (MDE/BDE)

- Prozess- und Qualitätsdatenerfassung (PDE/QDE)