Gute Vorbereitung zahlt sich aus – informieren Sie sich über alle teilnehmenden Aussteller und das gesamte Produktspektrum, das auf der SPS präsentiert wird. Treffen Sie so gezielt die richtigen Geschäftspartner.

Auf dieser Seite finden Sie alle Aussteller der SPS 2025. Die Online-Ausstellersuche gibt Ihnen frühzeitig einen Überblick über die teilnehmenden Unternehmen und wird täglich aktualisiert.

Nutzen Sie die verschiedenen Filterfunktionen, um konkret nach Produktgruppen, Hallen u.v.m. zu suchen. Die Filter können auch beliebig miteinander kombiniert werden, so dass Sie die Suche ganz gezielt auf Ihre individuellen Kriterien anpassen können.

Aussteller der SPS 2025

MTA GmbH

Über uns

MTA – Innovative drive solutions

Unique product technology, future-oriented solutions and innovative spirit are the cornerstones of MTA.

MTA GmbH specializes in the development of highly efficient, high-performance drive technology (synchronous technology) in compact installation spaces. The development process, product qualification and production take place entirely at the site in Ennsdorf (AT). The focus is on drive solutions based on synchronous technology for efficient integration into customer machines. MTA drives cover all areas of stationary conveyor technology, mobile robotics and, above all, general mechanical engineering.

The customer structure consists of market-leading manufacturers in various industries. One focus is mobile robotics. The main success factor here is the high motor performance in the smallest installation space. Customers benefit from MTA's flexibility and innovative strength. In addition, all drives can be supplied with motor controllers developed in-house and precisely matched to the solution.

Partner for innovative solutions

Fast, tried-and-tested solutions ensure that projects run smoothly and customer machines are efficient. To this end, MTA offers a comprehensive portfolio of different standard products and system solutions, which can be integrated into the system as required. The applications are realized promptly with the necessary flexibility and implemented in the product so that they correspond optimally. Our engineers are on hand to provide advice throughout the entire project management process, from development to commissioning of the product on site. This all-in-one service ensures that the project is handled in line with requirements and offers the best possible functionality.

Trade fair innovations from MTA

At SPS, MTA GmbH will be showcasing the latest innovations in the field of mobile robotics in Hall 4 at Stand 4-383. Among other things, an AGV fully equipped with MTA drives will be presented. Compact differential drives, gearless direct drives for fastbots and powerful drive-steering drives for omnidirectional vehicles will be presented, as well as drives for all types of load handling.

With its revolutionary drive technology and its complete product range of differential and omnidirectional drive units, MTA creates unlimited possibilities in the field of driverless transportation systems.

For the control of AGV and AMR drives, MTA GmbH is presenting an innovative control concept with integrated safety functionality. Prefabricated drive-related software functions simplify programming and reduce commissioning times. Full digitalization, a vertical communication concept and reduced interfaces guarantee optimum diagnostic options for the entire control and drive train right through to the wheel hub drive with integrated drive electronics. Drive-related safety functions are executed directly in the integrated drive controller. Safety functionalities of the vehicle are bundled in the upstream MTA drive controller and linked to logical vehicle functions in the freely programmable application area of the controller.

In the field of highly efficient sorter applications, MTA GmbH presents gearless sorter drives in a compact design. The slim design and individual control of each individual sorter motor enables highly dynamic discharge and smooth motion sequences. Sorter motors from MTA have been proving their worth for years in the logistics centers of the world's largest online retailer of consumer goods.

Of course, MTA also offers the entire controller technology, perfectly matched to the respective application.

Keywords

- Antriebstechnik / Drive techlology

- Fördertechnik / Conveyor technology

- Robotik / Robotics

- Motoren / Motors

- Motor Controller / Motor controllers

Unsere Produkte

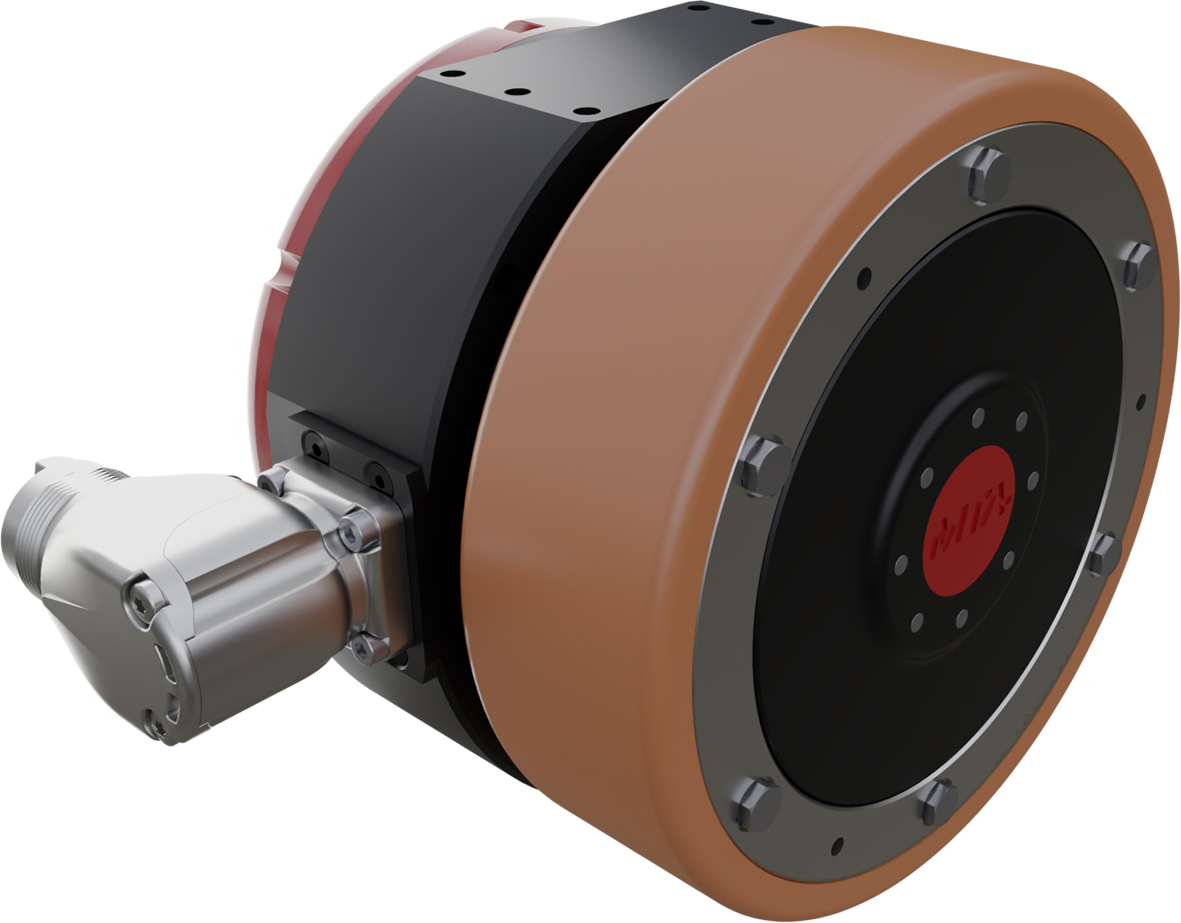

MTA WHEEL DRIVE OMNI - Revolutionary Groundbreaking Trendsetting

WHEEL DRIVES Omnidirectional

Next generation - Experience the future of drive technology

The innovative next generation wheel and steering drive from MTA sets new standards in performance and safety with its fully integrated drive controller. With a height of 203 mm and the smallest footprint, the omni-directional drive from MTA is the most compact in its class.

As part of a combination of several drive units, the drive can transport weights up to 2000 kg and has an endless rotating steering drive. The highest standards can be achieved through safety functions such as STO, SBC, SLS, SS1, SS2,... up to Performance Level e.

The drive system from MTA not only defines the next level of technology, but is also future proof, even as standards become more stringent.

Features

- Highly integrated traction and steering drive, “smallest in its class”

- Transports loads up to 2,000 kg with the smallest footprint

- Endless rotating axis

- Integrated brake

- Integrated drive controller with Safe Motion Functions STO, SBC, SLS, SS1,… via FSoE

- Simple wiring of all components via one hybrid cable

- Integrated redundant absolute encoder multi-turn capable no wiring and no external end position sensors necessary

- Industry 4.0 ready – data transfer via EtherCAT

- Drive manager with automatic controller tuning

- Low system complexity leads to quicker ROI

- Maintenance-free

Condition monitoring

Our innovative system uses the power of EtherCAT, a state-of-the-art communications protocol, to ensure seamless and efficient data transfer.

This not only allows you to control and optimize your drive systems in real time, but also to carry out diagnostics and implement advanced condition monitoring. These functions allow you to identify potential problems early and maximize the availability of your AGV fleet.

Our solution not only offers you improved control over your systems, but also greater reliability and efficiency in operation.

MTA - Your partner for mobile robotics

MTA is a trustworthy partner that stands for the highest quality standards and comprehensive support in the development of your solutions! We are at your side from the fi rst request to the fi nal release test.

Our products are tested under the toughest conditions in a specially created infrastructure to ensure that they meet the highest standards.

With our complete package from a single source, we lead your project to success.

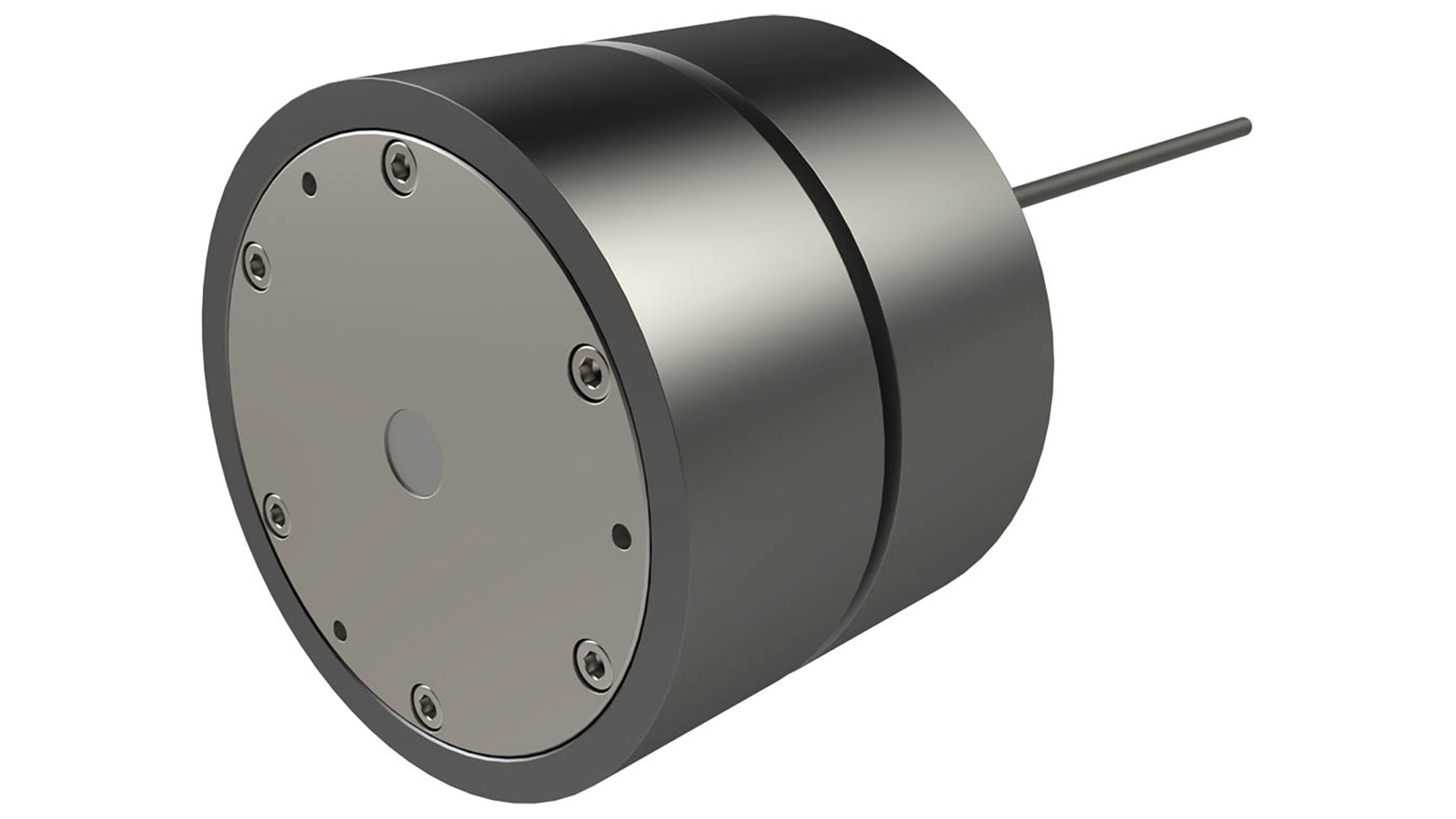

MTA WHEEL DRIVE DIFFERENTIAL - Gearless Intelligent Compact

POWERFUL, EFFICIENT, REVOLUTIONARY

Our gearless direct drive for tight spaces

Our gearless direct drive is characterized by its innovative technology, which dispenses with the use of a mechanical gearbox.

This results in an extremely compact design that offers advantages in various applications in mobile robotics. This drive is particularly suitable for installation situations where space restrictions and efficiency are of the utmost importance.

Expand the application possibilities of our gearless direct drive with the version with integrated motor controller, which combines all safety functions up to Performance Level e (PL e) as well as various communication interfaces.

Features

- Gearless: By eliminating the gearbox, the system operates particularly quietly, as disruptive noises and vibrations are minimized. The service life is drastically increased.

- Efficiency without compromise: Our solution combines compactness, power and efficiency for outstanding performance.

- Space-saving: The extremely compact design reduces the space required.

- Intelligent: Option with integrated motor controller for precise control and maximum performance.

- Wheel replacement: The wheels can be replaced simply and easily.

Field of application

The innovative drive opens up unlimited application possibilities, ranging from warehouse technology and order picking to cleaning technology, handling robots and vehicles for serving and courier services.

Options

A wide range of options enables unlimited application possibilities in various fields of application.

- Version with high-resolution encoder system and brake (holding brake with emergency stop function) for operation with decentralized motor controller

- Version with integrated brake (holding brake with emergency stop function), integrated motor controller, redundant multiturn absolute encoder and integrated safety functions up to performance level e (PL e)

Fully integrated motor controller

With this version, MTA sets new standards in performance and safety. The integrated motor controller precisely controls speed, torque and position. In addition, numerous safe motion functions up to performance level e (PL e) are available. Our innovative drive uses the power of EtherCAT and FSOE, a state-of-the-art communication protocol, to ensure seamless and efficient data exchange.

This allows you not only to control and optimize your drive system in real time, but also to perform diagnostics and implement advanced condition monitoring.

AGV/AMR SOLUTIONS - EVERYTHING from a single source! Your full-service supplier for drives on autonomous vehicles

TOTAL SOLUTIONS that set standards!

As a full-service supplier for drives for autonomous transport systems, MTA is the right partner for all conceivable motion sequences in mobile conveyor technology.

MTA’s drives are at home in open spaces, winding passages or on straight tracks. The MTA portfolio also includes many drives for load-carrying equipment. These include, for example, motor rollers and drum motors for conveying containers and pallets to and from the machine, lifting drives for transport platforms and telescopic drives for shuttles.

Our innovative drive systems are designed to maximize the performance, precision and reliability of your autonomous guided vehicle systems.

DIFFERENTIAL DRIVES

MTA wheel drives in the differential drive version are integrated drive units for free-moving transport systems (AGV/AMR) and rail-bound vehicles (shuttles).

Depending on the application, the differential drives are implemented with or without a gearbox (as a direct drive). The motor controller for the drive control can be either integrated in the drive or mounted separately.

A comprehensive drive portfolio of differential drives is available for total weights from 50 kg up to 2000 kg.

DRIVES FOR LOADCARRYING EQUIPMENT

Motorized rollers from MTA are used to carry containers (100 kg) or pallets (1500 kg). The drive controllers are integrated into the tube, which reduces the amount of cabling to a minimum.

The lifting and lowering of transport platforms on underfloor vehicles is realized with MTA lifting drives. Loads up to 1500 kg can be easily lifted and lowered in this way.

WHEEL-STEERING DRIVES

The combined wheel-steering drives are drive systems that allow maximum power density in a compact design. Several designs in different versions ensure maximum flexibility in vehicle design.

In our ALL-IN-ONE solution, the motor controllers for traction and steering including the functional safety functions and redundant encoders are integrated in the drive. The connections for the customer are reduced to the power supply and Ethernet communication in real time.

For use with an external mounted drive controller such as MTA motor controller for two axis or third-party controllers, the design with individually adaptable customer interface is available. Safety encoders or holding resp. operating brakes can also be used.

MTA DRUM MOTORS BELT MODULE DRIVE - Compact power package for product separation

REVOLUTIONARY ACCELERATED:

Innovative drive for highly dynamic movement processes

This gearless direct drive redefines innovation: Integrated directly into the pulley, this groundbreaking solution eliminates all the disadvantages of conventional geared motors, which are usually flanged to a pulley. The result? A compact, efficient drive unit without compromising performance. Groundbreaking technology that takes efficiency and reliability to a new level.

Properties

- Compactness: As no external gearbox is required, the size of the overall system is significantly reduced. This enables space-saving integration.

- Efficiency: The direct drive eliminates the energy loss normally caused by the gearbox. This leads to higher overall efficiency of the drive system.

- Low maintenance: Traditional geared motors require regular maintenance, especially of the gearbox. The gearless direct drive reduces the number of moving parts. No maintenance is required.

- Noise reduction: Geared motors produce noise due to friction and wear. The gearless direct drive eliminates vibrations and noise, resulting in reduced noise emissions.

- Faster response times: By integrating the motor directly into the pulley, the gearless direct drive enables faster transmission of torque and improved response time.

- Precision: The direct connection between motor and pulley enables precise control and positioning.

The impressive technical data of our drive system impresses with highest performance, excellent efficiency and a robust design that meets the requirements of demanding applications.

Application

Our drive is ideal for use in conveyor modules for product separation. Specially developed for the highly dynamic package processing of chaotic package fl ows, this belt module drive off ers custom solutions for separation systems and the precise alignment of packages. An innovation that redefi nes effi ciency and speed for modern logistics.

Functions

Alignment:

Rotated packages are aligned using highly dynamic acceleration processes.

Separation:

Package items arranged next to each other are separated for subsequent logistics. By means of accelerating processes, packages arranged in parallel are arranged one behind the other.

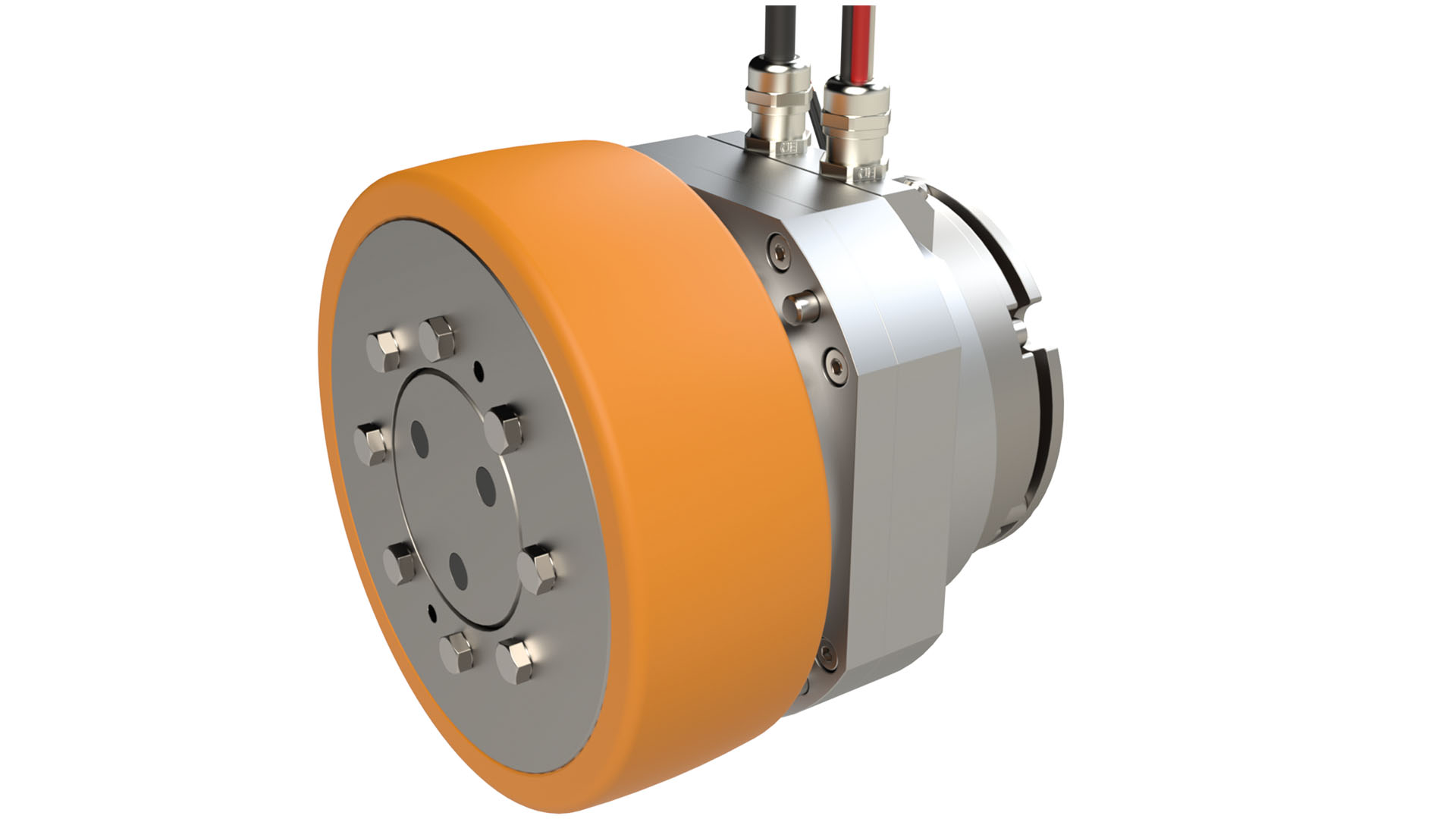

MTA WHEEL DRIVE DIFFERENTIAL - Powerful differential drives for all applications

COMPACT, POWERFUL, INTELLIGENT

Our product family for limitless possibilities

Our product family of differential drives enables unlimited application possibilities for every type of driverless transport system. Two product lines are available for the realization of scalable vehicle sizes, enabling flexible adaptation to different requirements.

For the smaller design, the version with integrated motor controller is available, which provides all safety functions up to Performance Level e (PL e) as well as various communication interfaces.

Features

- Compact design for a lightweight, space-saving vehicle design

- Maximum efficiency thanks to synchronous technology

- Intelligent thanks to option with integrated motor controller for precise control and maximum efficiency

- Maintenance-free thanks to a lifetime-lubricated gearbox

- Easy to change the impellers

Industry / area of application

The drives offer unlimited application possibilities, ranging from warehouse technology and order picking to cleaning technology, handling robots and vehicles for serving and courier services.

Travel movements

The drives can be used for universal forms of movement in differential or omnidirectional operation.

The compact design enables space-saving turntable drives for omnidirectional operation. The implementation for omnidirectional travel is possible by using Mecanum wheels.

In differential travel mode, precise cornering, outstanding accuracy and optimum travel performance are guaranteed.

Options

Many options enable unlimited application possibilities in various fields of application.

- Version with high-resolution encoder system and holding brake with emergency stop function for operation with decentralized motor controller

- Version with integrated holding brake with emergency stop function, integrated motor controller, redundant multiturn absolute encoder and integrated safety functions up to performance level e (PL e)

Fully integrated motor controller

With this version MTA is setting new standards in performance and safety. The integrated motor controller preciously controls speed, torque and position. Numerous safe motion functions up to performance level e (PL e) are also available. The innovative drive uses the power of EtherCAT and FSOE, a state-of-the-art communication protocol for seamless and efficient data exchange. This allows you not only to control and optimize your drive system in real time, but also to perform diagnostics and implement advanced condition monitoring.