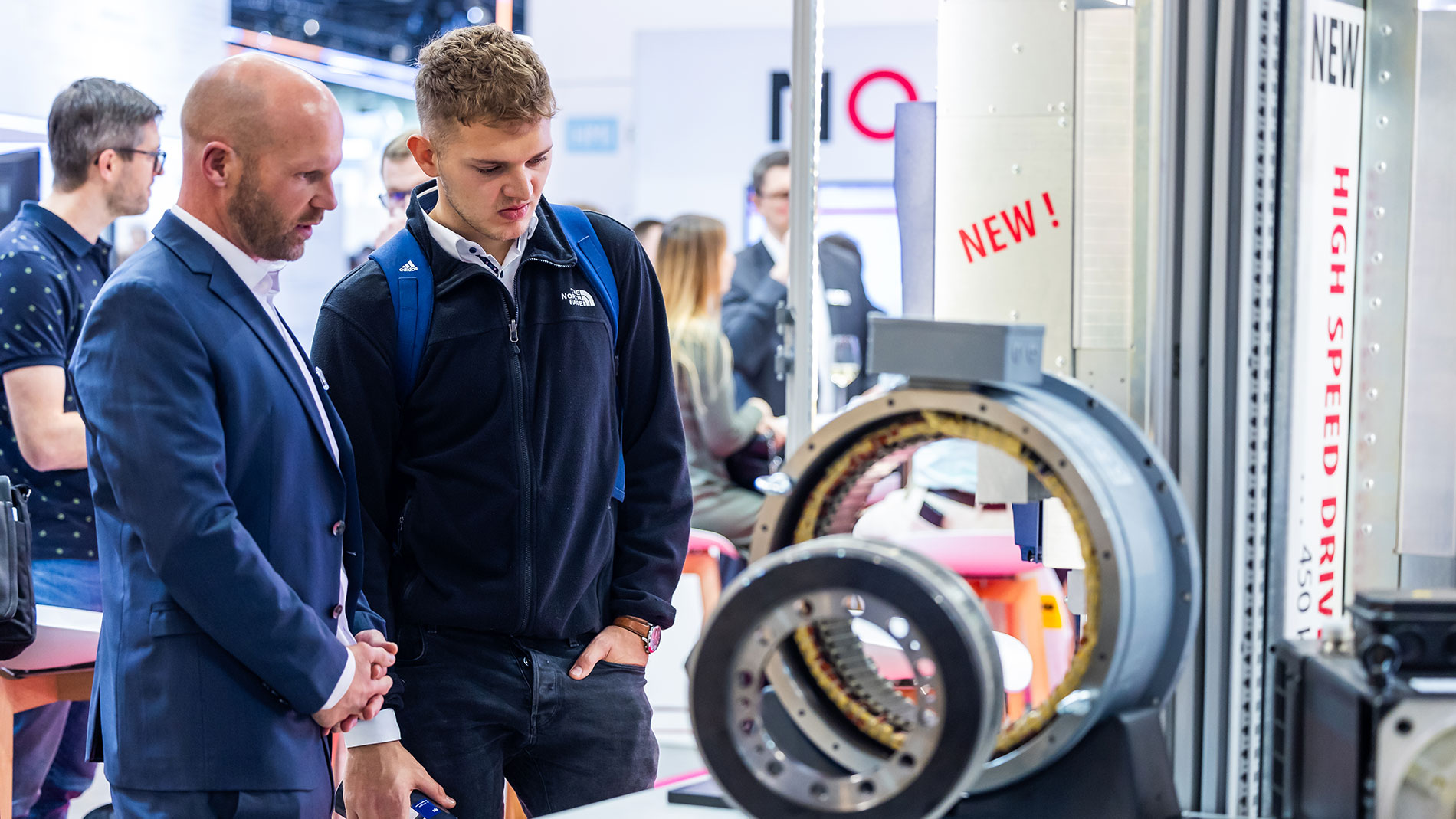

DEMO: Deep Learning-based Visual Inspection

Our system for automated defect detection sets new standards in quality assurance. It utilizes AI-based image processing to inspect weld seams on battery cell modules in real-time. The module is manually placed under a camera, and the system analyzes the images using a pre-trained deep learning model. Defects are instantly highlighted with color indicators: red signals flaws, while green confirms a flawless product.

The system enhances production efficiency through consistent, objective quality control and can be adapted for other products requiring visual surface inspections. With an increasing amount of data, the system continually improves, reducing the error rate over time. It can be operated locally or via cloud systems, with our "FCTRY CLD" solution offering secure and fast processing of sensitive production data on-site.

The result: a reliable and automated defect detection system that relieves skilled workers and ensures product quality during the manufacturing process.

![]()